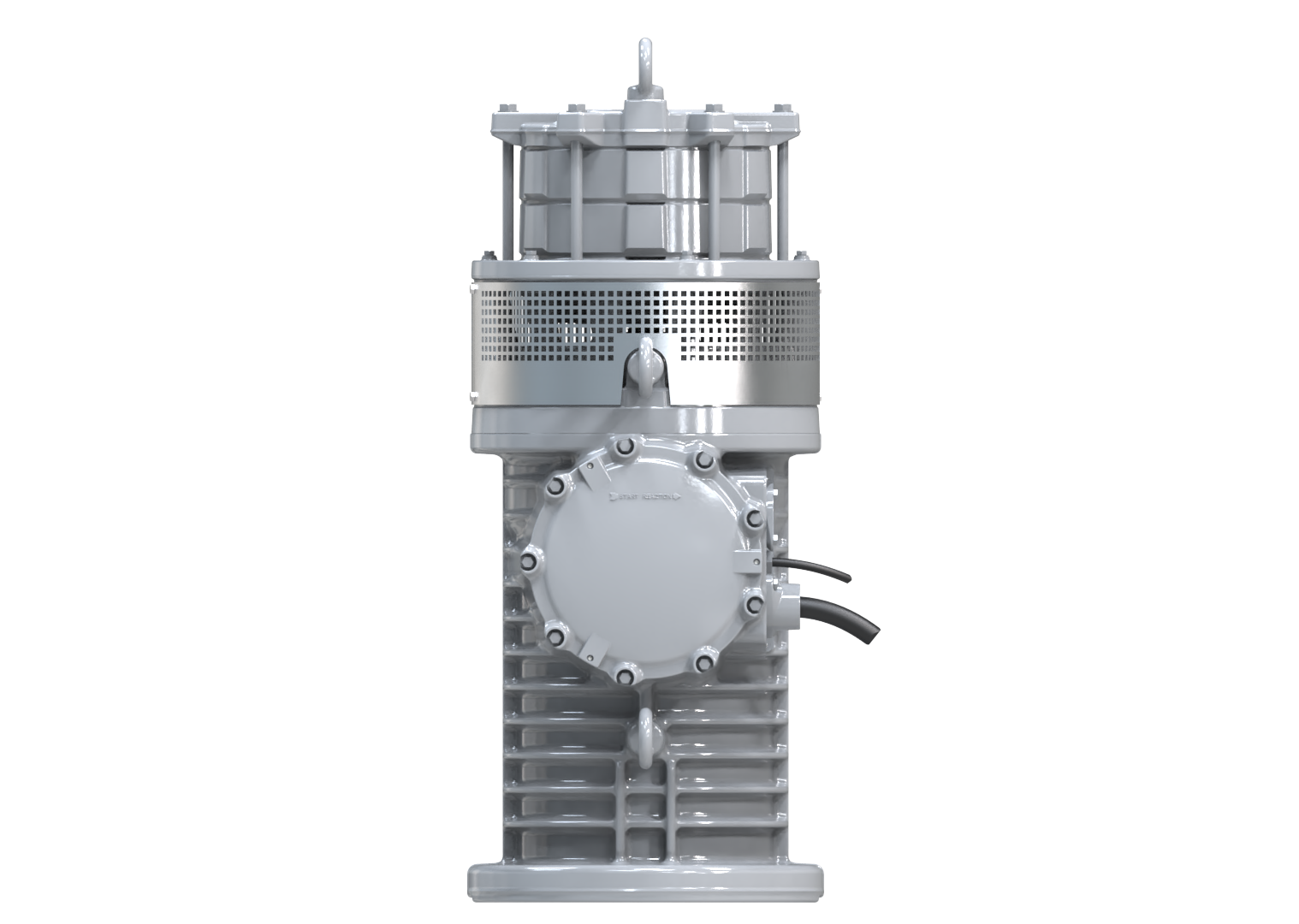

Xylem has launched the Flygt 2450, the only high-head fully submersible pump for mining applications that eliminates the need for extra infrastructure to handle abrasive water, significantly reducing total cost of ownership, it claims.

The pump drastically reduces wear and extends the time between servicing to up to 6,000 hours – three times the hours of standard submersible pumping equipment – due to a Hard-Iron hydraulic end and Dura-Spin diffuser technology, the company says.

diffuser technology, the company says.

At a large open-pit gold mine, in the US, operators replaced a parallel pumping system with a single Flygt 2450. To date, it has delivered 5,500 hours of continuous, trouble-free runtime without requiring maintenance, cutting costs dramatically, according to the company.

Building on this innovation, Xylem is also introducing the Flygt 2401, a redesigned version of the Flygt 2400 submersible pump. This versatile model offers mining application flexibility with two hydraulic configurations: one optimised for high head lifting and the other for high-volume flow. Additional enhancements allow for faster servicing and longer pump life, including a redesigned bearing arrangement, larger connection box and streamlined pump housing.

Ken Albaugh, Director, Dewatering Services for Xylem, said: “Water shouldn’t have to be a complicated aspect of mining. Anything we can do to simplify water management enables the mine to boost efficiency and productivity. The Flygt 2450 addresses the specific challenges that mine water presents and makes water management simpler, safer and less expensive.”

The post Xylem looks to simplify water management with Flygt 2450 pump appeared first on International Mining.