Sign up for CleanTechnica’s Weekly Substack for Zach and Scott’s in-depth analyses and high level summaries, sign up for our daily newsletter, and/or follow us on Google News!

At a dusty solar site outside Culcairn, New South Wales, a tracked robot methodically rolled between rows of steel posts, hoisting large photovoltaic panels with a vacuum arm and placing them onto pre-aligned mounting structures. In the brutal Australian sun, where manual laborers need regular hydration breaks and safety protocols for heatstroke, this squat machine didn’t stop. It marked a quiet inflection point in the story of solar construction. The robot, built by Shanghai-based Leapting Technology, was not an experiment. It was a production unit doing production work. And it just replaced the output of a crew of three or four installers on one of the country’s biggest utility-scale projects.

The global solar industry has a speed problem. It’s not that we don’t know how to build solar plants, as gigawatts of new capacity are being added annually. The problem is the scale and velocity required to meet climate goals outstrip our ability to find, train, and deploy the human muscle to physically install it all. According to the IEA, the world needs to install over 800 gigawatts of solar annually by the early 2030s to stay on track for net-zero. That translates to hundreds of millions of modules every year. The act of moving a 30-kilogram glass rectangle from a pallet, hoisting it overhead, aligning it precisely with a torque tube, and securing it — again and again in the heat, for weeks on end — is not just time-consuming. It’s physically punishing. Labor shortages, injuries, and burnout are all limiting throughput. Automation isn’t just a convenience, it’s becoming a necessity. This is far from the early days of solar when side of the road pickups for unskilled day labor were the norm.

Leapting’s robotic system, deployed commercially for the first time at Culcairn, is a tracked vehicle with a six-axis robotic arm equipped with an AI-guided vacuum suction gripper. It uses 3D sensors, posture recognition algorithms, and onboard simultaneous localization and mapping (SLAM) navigation to position itself within millimeter-level precision. Once loaded with a stack of panels, it autonomously moves through the array, identifies the mounting points, aligns each module, and places it. According to field data from the project, the robot was installing panels at a rate of about 60 per hour — roughly 480 in a standard eight-hour day. That’s roughly three to five times faster than a typical human crew of the same size, which often tops out at around 100–120 modules per day due to fatigue, heat limits, and the need for team coordination.

This is part of a broader industrial trend. In the United States, Rosendin Electric demonstrated its own semi-autonomous system in Texas that allowed a two-person team to install 350 to 400 modules per day, a clear step-change from traditional methods. AES Corporation has been developing a robot called Maximo that combines placement and fastening with computer vision. Trina Solar’s Trinabot in China operates in a similar space, with prototype systems demonstrating 50-plus modules per hour. The range of architectures varies — some systems are fully autonomous like Leapting’s, others are designed to augment human crews — but the theme is consistent: labor productivity is being multiplied. In an industry where time-to-energy is critical, shaving weeks off the construction schedule directly reduces costs and increases net revenue.

What sets Leapting’s system apart is its full autonomy. Once staged and calibrated, it handles navigation, obstacle avoidance, and precision placement on its own. That’s a major distinction from power-assist systems that still rely heavily on human inputs. Of course, that autonomy comes with its own limitations. The robot needs relatively well-graded terrain and spacing that accommodates its 2.8-meter-wide chassis. Sites with steep slopes, heavy mud, or dense rock will slow or stall it. And while its AI can adapt to light changes, intense glare or poor visibility can degrade sensor performance. It may also require a human to follow behind for final mechanical fastening, depending on the racking system used. In that sense, Leapting’s robot is still dependent on design standardization in utility solar — the flatter the site and the simpler the racking, the better it performs.

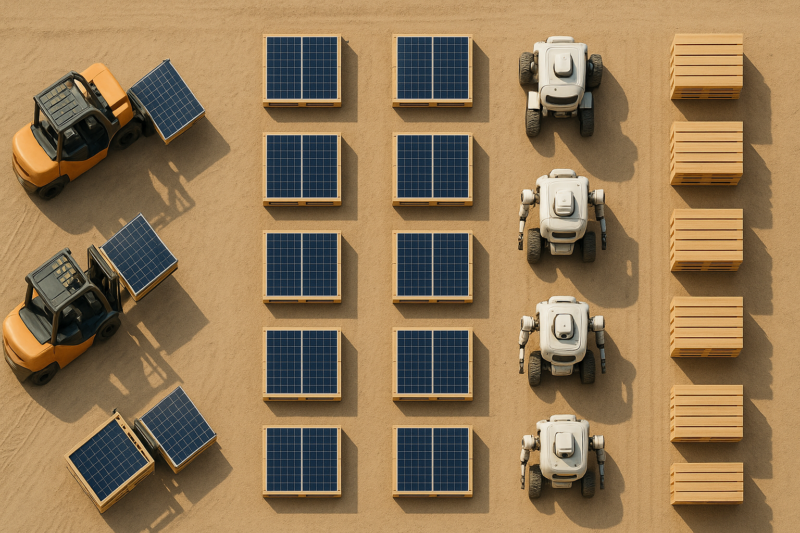

There’s also the question of logistics. A robot can’t magically summon its own panels. It needs a constant feed of modules staged within a short distance of its work area. That means forklifts or telehandlers need to be synchronized with the robot’s movement to prevent downtime. In projects where layout planning and material flow are already tightly managed, this isn’t a major hurdle, but it does require a shift in thinking. Construction managers must now plan for robot logistics the way they’d plan crane movements or concrete pours. And while the robot doesn’t need breaks, it does need recharging. Leapting hasn’t released detailed specs, but the powertrain appears to be electric, likely using an LFP battery system that can be swapped or recharged overnight. Endurance for a full shift is achievable, but double-shift operation would need charging infrastructure in place.

From a financial perspective, the business case is compelling. Labor makes up a significant portion of engineering, procurement and construction cost in utility-scale solar. If one robot can reliably replace three to four workers and do so with fewer errors and injuries, the payback period is short — especially if the machine is leased or reused across multiple projects. Leapting claims installation cost savings in the range of 30%, though real-world figures will depend on project specifics and how well the robot is integrated into the workflow. A case study from the Culcairn deployment found total project timelines were reduced by roughly 25%, thanks in part to the robot’s consistent throughput even during high-heat periods when human labor would typically slow.

The value proposition of autonomous robotic outdoor workers is being demonstrated in Australia, but it’s going to be essential in many places around the world as wet bulb temperatures make it impossible for human labor to work. Think construction, agriculture, road work. During the installation of the Culcairn Solar Farm in New South Wales, the area experienced peak daytime temperatures of 36.2°C (97.2°F) on January 11, with several other days exceeding 34°C . We are moving into a world where in places closer to equator summer daytime work will often be impossible. The searing and arid Australian summer Outback is a part of more countries’ future.

There are other implications here. If solar construction begins to resemble a factory floor — highly repeatable, automated, and scalable — it changes how we think about energy infrastructure. A future where fleets of machines handle panel mounting, O&M drones conduct thermal scans, and autonomous brush bots clean panels weekly is no longer speculative fiction. It’s just smart engineering. Solar becomes more like manufacturing: controlled, modular, and fast. That, in turn, makes it easier to finance, deploy, and maintain. And it means the workforce evolves too—not away from people, but toward people who supervise, troubleshoot, and orchestrate the robots.

Leapting’s robot is still early-stage. It’s only been deployed commercially in a handful of locations: Culcairn in Australia, parts of Adani’s 30 GW Khavda park in India, and trialed in China’s high-elevation and desert solar zones. But the direction is clear. The future of solar construction will be faster, safer, and more precise—not because of human brawn, but because of robotic repetition. There will still be humans on-site, but their role shifts from lifting panels to managing throughput. Just as cranes and excavators changed civil construction, so too will robots like Leapting’s define the next era of solar deployment.

Whether you have solar power or not, please complete our latest solar power survey.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one on top stories of the week if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy