Sign up for CleanTechnica’s Weekly Substack for Zach and Scott’s in-depth analyses and high level summaries, sign up for our daily newsletter, and/or follow us on Google News!

Recently, I had the opportunity to sit down Simon Todd, PhD geologist, founder of Causeway Energies, and expert on geothermal. This is the transcript of the second half of our conversation, lightly edited.

Michael Barnard [MB]: Hi, welcome back to Redefining Energy — Tech. This episode is powered by TFIE Strategy, guiding investors toward climate-smart bets that will win in the real world and the market. I’m your host, Michael Barnard, and my guest today is Simon Todd, Managing Director of Causeway Energies, a Ph.D. in geology and an expert in geothermal energy. This is the second half of our conversation, spanning the very useful, the more speculative, and the more science fiction aspects of the space.

There are two or three things I’d like to pull out of that because they’ll become important in about 10 minutes. That’s a bunch of electronics on a drill head underground, and that’s a drill face working against shale, which has a certain hardness. If the drill bit ran into an igneous extrusion, what would happen to the effectiveness of the forward movement of the drill bit, in your professional opinion as a geologist?

Simon Todd [ST]: That’s one of the other advances from oil and gas drilling that’s now being transferred to geothermal. PDC bits, which are typically used in drilling, have been adapted. Modified mud mixtures, mud weights, weight on bit—all of those parameters from the shale industry have been speedily and incrementally applied to increase the rate of penetration. Horizontal wells that would have taken weeks back in 2005 now take just a handful of days because of continuous adaptation and improvement. I think we’re seeing the same thing happening, in bits and pieces—pardon the pun—in geothermal and EGS.

From my perspective, Fervo are the leaders in this. They’ve been very systematic between Project Red and the Cape project, incrementally learning, well by well, how to drill through granite—which is a different proposition from shale. Some of my drilling friends actually say that, in some cases, homogeneous, consistent rock like granite is easier to deal with than layered, heterogeneous, or inconsistent rocks. It’s really interesting to see these learnings being transferred, and Fervo, in particular, has been publishing and demonstrating that they are creating learning curves for drilling that look a lot like what we’ve seen over the past 20 years in the shale industry.

MB: Let’s actually ask the really nerdy, really basic question: why are we drilling through granite instead of through shale for geothermal?

ST: For geothermal, you need two things: temperature and some kind of heat transfer mechanism that will work for you. Typically, it’s permeability rather than conduction that people are relying on. The temperature aspects are often a consequence of the geological evolution of the area you’re looking at. The Basin and Range area in the western United States—Nevada and Utah—has had a geological history over the past 70 to 80 million years involving continental collision, intrusion of volcanics, intrusion of granites, and then a return to extension, creating the literal Basin and Range pattern you can see on topographic maps.

The crust that was previously compressed is now being pulled apart, and that thinner crust elevates the heat flux, bringing the hotter material closer to the surface. That shallower, hotter heat sits in the bedrocks that form the region—granite, metamorphic rocks, and some superficial sedimentary rocks as well. It’s the geological convergence that causes the play to be in granite or volcanic rocks. In Iceland, of course, it’s mostly basalts—volcanic rocks they have to drill through—because that’s how the island was formed.

Does that make sense?

MB: It does, probably because I’ve spent way too much time looking at limestone and shale over the past four years. Also, to a certain extent, limestone substitutes—like basalt—have come up, with people claiming they’re going to use basalt instead, despite its different characteristics, like 6 to 8% quicklime compared to 65% in limestone. It’s not a great source. I’m not going to name names, but $300 million of U.S. money has gone to a firm whose entire purpose is to replace limestone with basalt in cement. To simplify it, limestone—the stuff we make marble countertops and cement out of—is much more suitable.

The stuff in southern Florida is sedimentary rock that comes from old seas, where seashells and carbonates filtered out of the ocean over millions of years, compressed under gravity, and were then uplifted to where we can access them. Shale comes from old swamps and inland seas with high biomass that settled to the bottom, compressed into layers, and over geological time formed hydrocarbons from that biomass, then were uplifted to where we can now drill into them. But these rocks haven’t gone through the metamorphic process of being exposed to enormous heat, so they’re softer. They’re easier to mine, which is why we like mining limestone and use it for cement.

But when we get to rocks that are heat-bearing, they’re either metamorphic—changed into harder rocks—or molten rocks that have solidified. In both cases, granites and metamorphics tend to be in places where there’s enough heat closer to the surface. If you have a big limestone or shale bed, it means it hasn’t gone through that process, so the heat is deeper down.

ST: Yeah, reasonable assertion—sort of 50/50, Michael. I think it’s probably worth talking about different geological settings for deep geothermal. In the UK and Ireland, for example, we would probably talk about two main geological settings. One is what we call hot sedimentary aquifers, or HSA. This is where a sedimentary basin is still somewhat intact, and you have rocks—shales, limestones, sandstones—buried to variable depths. With the geothermal gradient increasing with depth, by the time you get to around 3 kilometers in the UK and Ireland, you might be expecting to get close to 100 degrees Celsius.

MB: But that’s testing through sedimentaries, which are easier to drill, align with fracking drilling techniques and technologies, and are aquifer-based—which by definition have a great Darcy outlook, whatever the specific Darcy numbers are.

ST: The numbers will deteriorate with depth because what happens to those rocks is they get compressed. The ones with porosity have those little pores filled up with what we call diagenetic cement. Without artificial fracturing, you end up with much less permeability. The next part of the process geologically is that the rock gets buried by a mountain and undergoes metamorphosis. The other type we have in the UK are radiogenic granites. These are granites of variable age and variable heat flow, where the additional heat flow comes from radiogenic heat as well as the general heat flux.

One of the earlier EGS projects in the world is in Cornwall, where Geothermal Engineering Ltd. has drilled into a natural fault system in the granite. They’ve drilled two boreholes—one deep down to 5 kilometers, which is the depth needed to reach meaningful temperatures for the turbines—and a water injector well that’s a little shallower, around 3 kilometers. They’re enhancing natural fractures in that fault zone. They did a fabulous job managing societal expectations around induced seismicity and related concerns. They’re about to come online with a power generation plant, but the whole thing will only be about 5 megawatts of electricity. Scaling that up stretches my imagination. It’s a real project in the UK, but I don’t think it will ever be a big thing—at least not in my lifetime.

When you think about the Basin and Range systems or drilling on the flanks of active volcanoes in Indonesia, New Zealand, or Iceland, we’re really talking about a third type of system: volcanic active magmatic zones. In these areas, the rocks aren’t particularly porous but are typically naturally fractured, and you have hot, typically brackish to saline fluids moving through them by convection. This leads to a distinction between two types of systems. One is referred to as conductive, where the system is naturally dry and heat movement happens primarily through heat flux conduction, with little or no water in the fractures.

The other one people are now referring to is convective systems, where there’s a natural convection process with faults and fractures, and very hot water circulating because of the high geothermal gradients. That’s typically where conventional geothermal power plants have been located, which is where we started this conversation. I hope that helps draw some distinctions.

MB: So now we’re getting into the almost science fiction–type geothermal stuff. So far, we’ve been talking about tapping heat that’s readily available at high temperatures—collections of volcanoes that are temporarily inactive, like in Iceland and New Zealand. We’ve been talking about aquifer-based systems a few hundred meters underground. We’ve talked about shallow geothermal at around 100 meters. Then we talked about deeper aquifers, where it’s still relatively easy rock but you start losing Darcy, and with that, you start losing the interest of people who aren’t nerds like us—and of the people who actually want to make money off geothermal—because it becomes an economic issue.

Now we get into some of the more science fiction–type ideas. Let’s talk about it. There’s a bit of an alphabet soup: there’s advanced geothermal, enhanced geothermal, deep geothermal, Eavor’s closed-loop geothermal—which is different from the closed-loop geothermal you were talking about earlier. Why don’t we start by briefly characterizing Eavor’s closed loop versus normal closed loop, and what the key differences are?

ST: Yeah, so Eavor is closed loop. What they’re doing is going deep for heat with the aim of combined heat and power, or power generation from that heat. Their model is a closed loop that’s effectively a big U-tube in the subsurface. Their original pilot project in Canada had two horizontal wells drilled from points 2 kilometers apart, where they steered in the subsurface—at about 2 kilometers depth—for the toes of each horizontal well to meet, like the Channel Tunnel. Again, another directional drilling technology from oil and gas has proved very useful in geothermal. Their big claim is that instead of using standard steel casing to keep the borehole open, they’re using a chemical compound, something like a liquid casing.

They’re circulating water around that big, kilometer-scale U-tube. That’s what they’re doing in Germany right now, though we’re not hearing a lot of news about exactly what’s happening or what progress is being made. In that German project, they’re creating a bunch of those U-tubes underground from single parent wells drilled from the surface, effectively building a subsurface radiator of U-tubes. We studied the basic concept of deep closed loop ourselves and were quite excited about it when we got started. The basic problem, again, is conduction. When you inject a cooler-than-formation-temperature medium—whether it’s CO₂, which they sometimes talk about, or water—into that big U-tube, the immediate effect is that the rocks near the closed loop borehole start to chill.

Because conduction is slow, what happens is a cooler thermal halo or bubble expands out from the borehole. In the exiting temperature profile, you see a very rapid decline from the original bottom-hole temperature—sometimes as much as 75%—in the first few hours, days, or handful of weeks. Then that curve asymptotes to what I mentioned earlier: a pseudosteady-state decline at a temperature that, under good conditions, is about half of what you started with. Under poor conditions, it’s even less. That slowness of conductivity in rocks is not a friend to closed loop systems.

What we found in our economic modeling is that you need a gazillion light kilometers of borehole to harvest enough heat, and the temperature of the formation has to be significantly above the temperature you need for the turbine in order to be useful. You’re still having to drill much more than you would if you were just drawing heat out of water. I’m still kind of interested in deeper closed loop, but I see more opportunity in the relatively shallower subsurface—less than a kilometer deep—where I can get a little more temperature and a better delta T on my source heat, which helps the heat pump system significantly. But I don’t have to spend a fortune putting in kilometers and kilometers of deep borehole.

I actually did some math two or three years ago and figured out that, for a megawatt, we could do the same job with, say, 100- to 200-meter-deep closed-loop boreholes compared to a one-kilometer-deep borehole. We could do the same job. The drilling costs shift enormously as you go deeper, so it makes economic sense to stay shallow. If you can also optimize the heat pump efficiency—even to the point where it can handle 15 degrees Celsius heat and lift it to 120 degrees, like we did at Southwest Research Institute—then the economics start to look really interesting.

MB: There are two or three things about that. First, the longer you drill underground, the more the risks accumulate. That’s the first point. Horizontal drilling has achieved amazing things, but every additional kilometer adds risks to the drill, adds duration, and adds costs.

Their German project is 60 megawatts of heat and only 8 megawatts of electricity because, once again, with the organic Rankine cycle, they’re working off a lower-quality heat source that’s actually going to degrade over time, as you point out, geologically. They’re using different refrigerants to extract less efficient amounts of work from it, and that’s just the nature of the beast. I don’t personally rate their chances for success. I think it’s very interesting, I’m glad they’re trying it, and I’m amazed we can have drill heads meet two kilometers underground—that’s insanely precise and amazing. So full props to the drillers. Okay, so that’s closed loop—deep closed loop—Eavor.

Then there’s enhanced geothermal, and Fervo is kind of the front-runner in that. You’ve alluded to it a few times, and you’re more optimistic about Fervo than I am, but you’re also much closer to it. If anyone wants an opinion, they might take yours rather than mine. So tell us about enhanced geothermal—and why is it EGS instead of just EG?

ST: It’s an enhanced geothermal system. The terminology gets a bit like spaghetti soup here. As for Fervo, I agree—I actually think that if this becomes a real thing, they’re the leaders. I admire the way they’ve systematically worked through the technical challenges of transferring shale horizontal drilling and fracking techniques over to geothermal. They’ve also thought really carefully—or as carefully as they can—about the offtaker and how to build a value proposition around it. The jury’s still out on whether it’s going to happen, right? I agree. What they’re doing is looking at these conductive and convective situations in the Basin and Range Province, licensing tracts of acreage in granitic and volcanic terrains.

They’re drilling vertically down to four or five kilometers, then going horizontal with the objective of joining up as many natural fractures as possible. They’re using hydraulic stimulation to open up those natural fractures, make them more permeable than they would be naturally, and also to generate new propagated fractures. As you mentioned earlier, they’re keeping them open with little grains of sand or quartz proppant. They’re throwing the shale playbook and kitchen sink at it. It’s really impressive how they’re applying directional drilling, the drilling learning curves we talked about earlier, and, for stimulation, using stage stimulation technology—a more recent development in the oil patch—to maximize the effect of each fracture stimulation along each section of the horizontal well.

They’re matching up a producing horizontal well with an injecting horizontal well, creating a convection-advection system underground in a layer of rock that’s several hundred meters thick and several hundred meters wide. They’re even using terminology from the shale patch, calling these “benches” where they place each doublet or pair of horizontal wells. They inject into the injector and abstract from the producer. The early results are good. They’re getting flow rates from the producer with reasonable calculations on power generation efficiency that suggest actual megawatts of electricity—not just thermal energy—from an individual borehole pair.

Secondly, they’ve now got a couple of years—maybe getting on three years—of data from their first project alongside the government’s FORGE project, which they call Project Red. The temperature and flow rate have stayed pretty steady. One worry would have been a rapid thermal decline, like you see with a shale well, but at least over three years of data, that’s not the case.

MB: It’s going to last longer than a shale well, at least.

ST: It appears that way. All right, there’s a lot to like about what Fervo is doing from a technical perspective, and that’s why I’m a little more optimistic than you are.

MB: But what about the economic perspective?

ST: For me, there are maybe three things to talk about here. The first is a technical one: will that two-year performance turn into 25-year performance? Is the flow rate and the temperature sustainable?

MB: That’s because they’re still taking heat out of a volume of rock with low flux for the volume of rock.

ST: Right. They’re currently saying, yes, it will, and that they will drill another bench to replace it in due course. They’re talking about 10 or 15 years out, not next week like in shale. That’s big question number one for Fervo. The second question is sustainability. And the third is the industrialization question that you raised in your article.

MB: By the way, the Fervo CEO left a comment suggesting I didn’t know what I was talking about and dismissed everything I’ve ever written on the subject. He was looking for a reason to.

ST: I thought he was quite polite actually compared to some of the other comments that you got.

MB: I didn’t say it was impolite, but he was looking for a reason. To be clear, I’ll be transparent: my research didn’t indicate that they were able to do multi-well per pad deep drilling. Turns out Fervo cracked that one—I got that wrong.

ST: That’s right.

MB: I suspect that’s going to introduce other problems. But let’s test two things: what’s the average depth of a shale oil well or a stimulated gas well?

ST: Similar to slightly shallower and total length is the same.

MB: But then there’s the rock.

ST: There’s the rock, and then there’s all the infrastructure, and so on.

MB: Because the rock—igneous and metamorphic rock—is harder to drill through than shale, I understand.

ST: I’d say the rate of penetration that Fervo is achieving is now becoming equivalent to shale drilling. In the circumstances they’re working in, that issue has essentially evaporated. The reason for that is the methodical, systematic learning of how to speed up drilling—well length by well length, well by well, project by project—which is an art form the oil and gas industry knows very well. There are still technical aspects that Fervo is learning about. On the more commercial side, I think there are big question marks. A lot of people in the geothermal industry still talk about baseload, but you and I know that’s not really the issue anymore. A lot of others in the industry, including Fervo, are starting to recognize that dispatchability is the real prize.

MB: And flexibility.

ST: Flexibility and dispatchability. I have to say, I heard geothermal folks talking about this five years ago at an early conference. One guy from Ormat, one of the leading conventional geothermal firms, spoke on a business model panel and said the competition is battery plus wind, battery plus solar. That still makes sense to me. It’s not really about baseload. I think it’s about flexibility and dispatchability.

MB: One thing here is, if they could get below $10 or under $100 per megawatt-hour at a coal plant site, and replace the coal plant with this, that would be better. But it still requires a specific type of subterranean geology, correct?

ST: Your resource for power generation is remote from the demand, so there’s an infrastructure issue. Within that, there’s a simultaneous equation to solve around dispatchability and flexibility. How would geothermal fit into that? Here’s the bottom line for me: maybe I’m too much of a geo-optimist, but I can’t completely get to Michael Barnard’s position that it’s a rounding error. Still, I don’t think it’s going to be hugely significant or material. I really shudder when I hear some of the recent hype about filling data center demand with material amounts of geothermal by the early 2030s. That annoys me because I think it reflects badly on the real opportunities in other geothermal applications.

The way I worry about it, big picture, is energy return on energy invested. If you assume for a minute that we could do EGS for more or less the same costs as shale oil drilling, the next big problem is that the energy density—and therefore the economic value of the product—is at least 15 to 25% of what you get from shale. And with shale, you’re getting most of it in the first hundred days.

MB: Right now, we’re at 2 to 4 EROEI—energy return on energy invested. The EROEI of shale right now is 2 to 4. Wind and solar are at 12 to 18. If geothermal—specifically enhanced geothermal—is getting a lower energy density result, it could end up with a negative EROEI. It could take more energy to drill and power the system than it produces, depending on the duration of the resource. The shale oil resource comes out rapidly. It takes a lot of energy to get it, but you get two to four barrels of oil for every barrel’s worth of energy you expend. If the resource lasts for 10 years, then the equation…

It’ll be interesting to see how it works out. But right now, even the best, most optimistic projections are saying $150 to $250 per megawatt-hour, which is way out of competitiveness. It’s nowhere near competitive.

ST: I did some math this morning, Michael, just to think about this. I took a shale well producing 5 million barrels over 10 years. By the way, Google says it’s about 1,700 kilowatt-hours per barrel of oil—an equivalency that will drive you mad. To even the playing field with geothermal, I stretched it to 20 years for the shale well. My thermal capacity came out to 48 megawatts for that. Fervo is saying they’ll get 12 megawatts electrical over a 25-year project term. When I ran the numbers, I gave $70 a barrel to the oil guys and $0.07 per kilowatt-hour to the geothermal guys.

The numbers are more than twice the value proposition. If that’s right—2 to 4 EROEI for shale wells compared to 12 for solar—and assuming you’ve built the full infrastructure and intermittency costs into that number, because sometimes I worry they aren’t, then even if they’re comparable, the big picture for geothermal is looking challenging.

MB: The thing I say about enhanced geothermal is that the capital costs are so high, they have to run at 90% capacity factors to make the economics work. They need a data center load and that kind of constant demand. So that’s EGS—we’ve talked about EGS. Let’s spend a couple of minutes on really deep geothermal.

ST: Let’s only spend 30 seconds. Right?

MB: Come on, talk Quaise.

ST: I’m a bit of an interested spectator with that stuff. I have to confess, I’ve taken a rather agricultural view of it: if it were doable, it would already have been done by the oil and gas industry.

MB: Let’s talk about the depths. Let’s start with the depths and the temperatures.

ST: The big idea is to go deep enough that you’re reaching supercritical temperature and pressure conditions, where the energy proposition is enormous compared to the depths that Fervo and others are targeting. The idea is that you drill one of these wells and you’ve got enough energy to substitute for a coal-fired power station right under your feet. You could do this anywhere in the world because the technology would allow you to drill deep enough—whatever the geothermal gradient—to reach the super-hot rocks. The technology challenges are miles and miles of drilling through harder, higher-temperature rock. Pressure isn’t as much of an issue, but temperature definitely is. And then, of course, there’s the question: what do you do once you get there?

How do you get the heat out? What are the systems that are going to be able to harvest supercritical heat and bring it to the surface? That part really does seem like an episode from Star Trek where the blob melted its way through the wall, right?

MB: My favorite point on this is about the electronics at the directional drill heads. All the technology just doesn’t work at those temperatures. All the electronics have to be replaced, all the drill bits have to be replaced, and the characteristics of the rock become more plastic. Everything that has been working well—what Fervo managed to pivot from shale to granite, from oil and gas to electricity—stops working. They have to invent new stuff. Now we’ve got microwaves and…

ST: For the lasers and the electronics, and some of the other temperature-dependent equipment, there’s a tempering comment I’d like to make. The temperature of the circulating fluid around the drill bit, the motor, and the measurement-while-drilling equipment is significantly different from the formation temperature. Mud acts as a lubricant for the drilling process, provides weight inhibition to prevent unwanted fluid inflow, and, in these circumstances, can also serve as a cooling aid. So the temperature challenge for electronics is definitely real, but a cooling mud system offers an opportunity to make that particular challenge more manageable.

MB: Closed loop and EGS both have black swans on their own and capital costs that make electricity unviable, though for different reasons. But deep geothermal is a flock of black swans—and they’ve got lasers strapped to their fricking heads. It’s science fiction.

ST: That’s enough now. That was three minutes at least.

MB: Let’s close off with what Causeway does and what your sweet spot is in this space. In my research, I described it as moderate geothermal uplifting with industrial heat pumps. Industrial heat accounts for about 10% to 25% of all global emissions, and about 50% of that is in the sweet spot for this approach. Tell us about that and about Causeway.

ST: We started out with the dream of power. Within a year, we pivoted to heat, but we didn’t give up on higher temperature heat. Most industrial heat demand is actually below 80 degrees Celsius. It’s only when you get into processes like drying and pasteurization that you move into the 150 degrees Celsius range, and it’s really only cement, metals, and some chemical processes where you need hundreds or even thousands of degrees Celsius. Today’s industrial heat pumps are more than capable of delivering sub-steam temperatures very easily with high COPs. They’re also capable of producing low-grade steam—around 120 degrees Celsius at five bars. There are now machines that can deliver up to 150 degrees Celsius. One of our expert advisors, Professor Neil Hewitt at Ulster University, is pretty confident about reaching even higher temperatures.

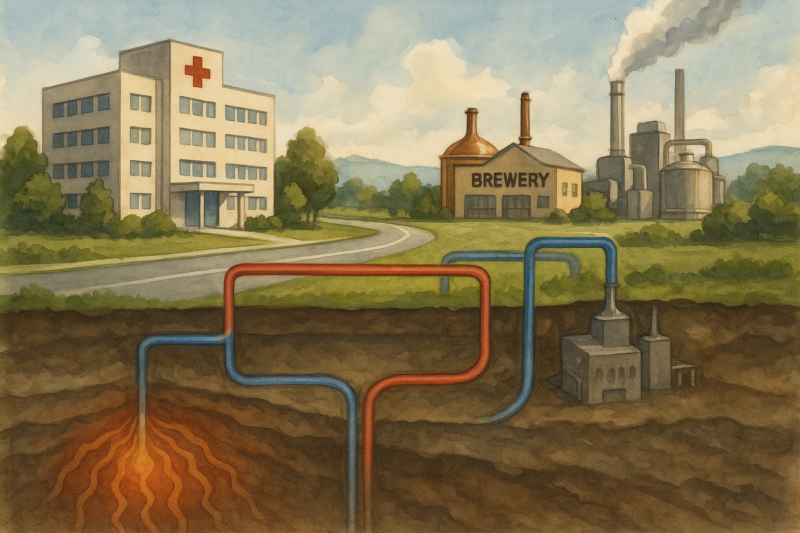

Industrial heat pumps are already a reality, particularly in Europe. What they’re typically doing there is using unwanted waste heat from fossil fuel heating systems and upcycling it so it can be used usefully as low-grade steam or very hot water. In our work with industrial heat pumps, we observed that the way the technology is progressing, we can now use lower and lower temperature heat—not just waste heat from fossil combustion—and still deliver the same results. This opens up large demand applications like water and space heating for hospitals, big buildings, and networks. We’re starting to think about low-grade steam, and we’ve been doing some work with a distillery on that. The heat pump technology is already there for that. The next frontier is getting to even hotter temperatures.

With the subsurface, the big aha for us was realizing that, given the efficiency of heat pumps to achieve temperature lifts of 60, 70, 80, even 90 degrees Celsius while still maintaining high or sufficiently high COPs, we don’t necessarily need to drill that deep for our heat. Twenty degrees might do. Thirty degrees would probably do very nicely. Sixty degrees would be even better. When we ran the numbers and compared the differences in COP relative to temperature increase with depth against the increasing drilling costs and risks with depth, we saw a Goldilocks zone—or sweet spot—emerge. It’s between 500 and 1,500 meters. You could go deeper than 1,500 meters in UK and Irish circumstances, but as I said earlier, at that point you probably need to move to geothermal systems to extract the heat, because the natural permeability would need to be clarified.

MB: Back to aquifer geothermal.

ST: In deeper aquifers—yeah. I mentioned earlier the example in Liverpool, where the deeper aquifer is only about 500 meters deep, but that extra 6 degrees Celsius compared to the shallow aquifer makes all the difference to heat pump efficiency and the delta T on the source—how much you can extract from that higher temperature. We’ve completed a number of feasibility studies that support the concept. The next step is moving toward a commercial pilot, and we have two or three customers in the UK who are interested.

We also had a brewery project in Nigeria, owned by a very well-known drinks manufacturer, where we advanced to testing the boreholes. Unfortunately, that drinks manufacturer sold the brewery and the project to a third party late last year. That project is unfortunately currently in abeyance. Hopefully the new owner will come around. That one was about six or seven megawatts of brewing and in-place cleaning of the brewing equipment, supplied by an unusually hot aquifer at only 650 meters deep, with 70 degrees Celsius underneath Lagos. There are a number of opportunities to progress toward something similar. We’re also really interested in the thermal energy storage model. When you get that right, the economics are really interesting—and so is the impact.

MB: People haven’t been talking about heat because it’s too boring. We’ve finally got people excited about heat pumps, but now we need to get them excited about this low-risk, widely accessible option. Let me ask you one question: aren’t you going to be interfering with drinking water from these underground aquifers?

ST: For shallow open loop, the permitting and regulation are much more rigorous when the water is of drinking water quality. It usually boils down to having to re-inject the water so there’s zero net abstraction of the resource. In some countries where regulation is more advanced, you also have to demonstrate that you won’t interfere with the chemistry or biology of the water, and that you won’t have your “milkshake sucked by somebody else’s straw.” You have to run numerical simulation models to show how thermal plumes will evolve. It’s all doable—it just takes longer than permitting and regulation for closed loop, because closed loop doesn’t interact with the groundwater at all.

MB: Then for moderate depth like the 500 to 1500 meter?

ST: This is where it becomes really interesting. In most parts of the world I’ve looked at, because the temperature and residence time of the water are higher in the rocks we’re talking about, the water interacts with the formation rocks and the chemistry, becoming brackish and then saline with depth. There’s a lot of data collected in the US and the UK showing that salinity increases with depth. By about 500 meters, the water is already brackish and not of drinking water quality. In principle, that means you aren’t exposed to the same regulatory constraints—at least once you get through the first couple of hurdles, because the environmental authorities will initially ask you to explain and demonstrate it. That pattern of increasing salinity continues with depth.

One of our emerging deep geothermal heat pump projects, which I’m hoping to secure the first phase of engineering for at a hospital in Northern Ireland in the next few weeks, involves an aquifer we expect to be somewhere between 650 and 1,000 meters deep. If we reach 1,000 meters, the salinity will be a couple of times higher, which introduces some additional issues—but all of them are manageable because we know how to handle scaling and similar challenges. It’s not super corrosive like some of the hotter geothermal brines, so we expect it to be easier to utilize that aquifer resource.

MB: The last question about this, how prevalent are these moderate depth aquifers?

ST: They’re not everywhere. For the UK and Ireland, we’re saying let’s start with the ones we know best. Ironically, we know about them because of oil and gas exploration.

MB: Of course.

ST: There was a little bit of geothermal exploration in the UK in the early 80s—the last time people worried seriously about energy security. We have legacy seismic information, other geophysics, and boreholes that were typically drilled for deeper oil and gas targets. Our target geothermal aquifers are shallower, so the boreholes have drilled through them. In the UK and Ireland, we really like four or five particular areas. That doesn’t mean it will work everywhere, but they are really good places to start. There’s an old oil field adage: if you want to find oil, drill where oil has already been found.

I think it’s the same for this type of geothermal utilization: we start where the subsurface risk is already lowered by legacy data and experience, ironically from oil and gas. For the more difficult rocks, I haven’t given up on closed loop. We’ve also just finished and submitted a report today to the Department for the Economy in Northern Ireland, where we’ve looked at a hybrid system called a standing column well. You can think of it as a hybrid between open loop and closed loop. It’s been used modestly in the United States over the past three decades. It circulates water around an open borehole that’s not cased off, so you’re getting heat from conduction as well as from advection.

The joy of it is that it works in modestly productive aquifers that only have fracture flow. These aquifers characterize much of the northeastern United States, where the technology originated, but also the UK and Ireland. We’re pretty excited about this. The advantage is that, because of the additional advection as well as conduction—and we’ve proven this now with some field testing, proving it for Irish rocks—they are three, four, maybe five times thermally more powerful than the equivalent closed loop system. Where you can’t do closed loop because of space, and you can’t do pure open loop because the aquifer isn’t productive enough, there’s this intermediate solution that looks really exciting. It reduces the number of boreholes and capital expenditure, which improves the economics. We’re really excited about that application as well.

We’re working on three or four applications. We want to be a developer and build an investment thesis around it. We’re putting project finance into it to turn it into a business model—everything from capital financing to the customer, through to a thermal purchase agreement, or it could be completely off balance sheet for the customer. Those are the kinds of business models we’re thinking about. There’s technology in the pipeline, but we’re really focused on making the nearly proven and proven technologies work in these combinations first, before going back to the blue-sky drawing board and doing things like supercritical CO₂ again. That’s what we’re about. Right now, we’re dealing with the chicken-and-egg problem of demonstrating the technology to customers, stakeholders, and policymakers.

We need first of a kind projects to do that. In order to do that we need some help.

MB: But that’s first of a kind projects in Ireland, not first of a kind projects. It’s being done elsewhere.

ST: It’s been done a few times. You found a couple of examples in your research. There’s another one just about to come online in Denmark. We found one two or three years ago—I might get this wrong—I think it was in Slovakia, where they were using a heritage geothermal well for heating tomato greenhouses. When the well declined, they put a heat pump on it. Those were unstoried pioneers, but it’s still very few and far between as far as I can tell, Michael. First-of-a-kind projects in Ireland or the UK are still a fair topic.

Another thing I’ve learned and relearned is that for a lot of the technologies we’re talking about, technology innovation and diffusion are still geographically limited, which amazes me given the digital world we live in. Time and time again, we find that for customers, consumers, and investors, we can point all day at Sweden—the European leader for geothermal, with 16 or 17 terawatt-hours of geothermal heat harnessed by heat pumps each year. We can point all day at the Danish example or the Slovakian example. It doesn’t mean anything to them until it’s in the neighbor’s backyard or in the neighbor’s facility.

MB: That parochialism is a problem. We have to look around the world, find the examples, the spots of the future, and adopt them locally much more rapidly. We are at two hours, which has been a great conversation. I’d like to close it off. I always like to finish by leaving you an open-ended opportunity to say anything you think is relevant from your journey, from your experience with heat—something we may have missed in the conversation.

ST: I would just go back to the why—both the strategic why and the personal why. The strategic why is that roughly 50% of energy emissions are associated with heat. We’ve made some good progress on electricity and power generation, and some good progress on mobility and transport—though there’s still lots more to do—but very little on heat. I think that’s a big, powerful why. And it’s amplified for me because it’s not just about emissions and sustainability; it’s also about security and energy resilience. For example, in Northern Ireland, there are no fossil fuels, and in the UK, fossil fuel availability is declining. There’s only a single gas field off the west coast of Ireland. So dependency on imported fossil fuels is a really serious matter.

And the number of bad actors that hold those fossil fuels is increasing, not decreasing, for everybody else. So the notion of affordable, indigenous, and therefore secure and sustainable heat is, I think, a wonderful prospect. As for the personal why—I’m not out to make a big fortune from this. My career with BP set my wife Fiona and me up reasonably well for the remainder of our lives. This has become a sort of last phase of the career, a legacy thing for me: just to make a difference, use the skills of extraction, learn some new things, and hopefully make a difference in the home countries and elsewhere.

MB: That’s great. I’m your host, Michael Barnard. This has been Redefining Energy-Tech. My guest today has been Simon Todd, Managing Director of Causeway Energies, Ph.D. in geology, and expert, as we’ve discovered over the past two hours, in geothermal energy. Todd, thank you so much for joining me.

ST: You’re very welcome, Michael. Thank you for the invitation.

Whether you have solar power or not, please complete our latest solar power survey.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one on top stories of the week if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy