Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

There are many minerals and other valuable components that have commercial value in wastewater and industrial waste. The problem is that extracting them can prove so costly that there is little room left for profit. Furthermore, the existing methods for extracting them have some negative impacts on the environment. BlueShift, a Boston, Massachusetts-based startup, says it has answers to those problems and has landed $2.1 million in seed money to build its first pilot project.

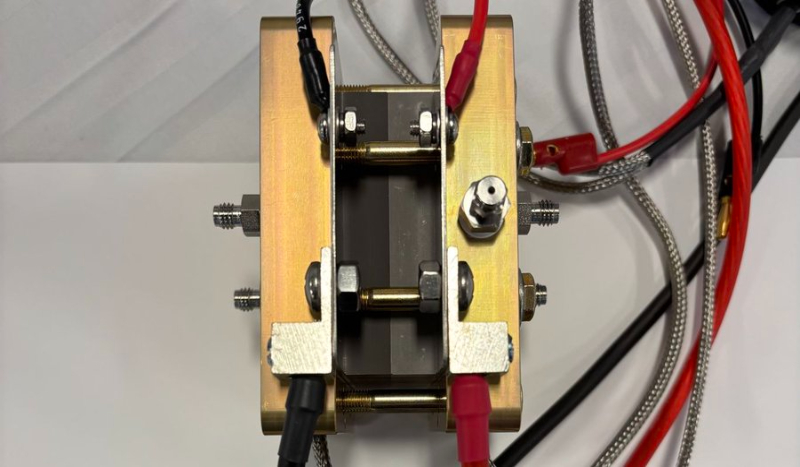

According to Axios, BlueShift has developed an electro-chemical cell that uses redox chemistry to extract minerals from industrial waste with low energy. ConocoPhillips is one of the companies that has contributed to the seed money funding. Venture capital firm Ridgeline and the Massachusetts Clean Energy Central also participated in the early funding round. The company was founded in 2024 and works out of climate tech incubator Greentown Labs and The Engine, an MIT platform that leverages new technology developed by its students and professors. BlueShift has also gotten support from the ARPA-E program at the Department of Energy.

Before we go any further, let’s define what redox means for those of us who flunked organic chemistry in college. Wikipedia explains that redox is a combination of “REDuction” and “OXidation” and was first used in 1928. Oxidation is a process in which a substance loses electrons. Reduction is a process in which a substance gains electrons. The processes of oxidation and reduction occur simultaneously and cannot occur independently. In a redox process, the reductant transfers electrons to the oxidant. Thus, the reductant or reducing agent loses electrons and is oxidized, and the oxidant or oxidizing agent gains electrons and is reduced. The oxidation alone and the reduction alone are each called a half-reaction because two half-reactions always occur together to form a whole reaction. We now return you to your regular programming, already in progress.

“BlueShift was founded with the mission of promoting economic resilience by unlocking underutilized resources using advanced technologies,” said BlueShift Founder and CEO Deep Patel in a press release. “And there is perhaps no other class of resources better positioned to benefit from this mission today than that of critical minerals and rare earth elements. Given the dramatic scale of environmental degradation, operational inefficiencies, and global trade imbalances plaguing this market, we felt it was imperative to develop a more sustainable, scalable, and geo-politically stable source of these vital resources. The result is a new system that addresses all of these issues while also offering a low cost, energy efficient method for direct carbon dioxide removal from our Earth’s ailing oceans.”

Patel previously worked at Amazon’s moonshot Lab126 on direct air capture. He said the bulk of the funding will go towards developing a shipping container size unit in Boston harbor that can produce metals like nickel and rare earth minerals from industrial waste. Regarding the partnership with ConocoPhillips, Patel said, “We believe that the oil and gas sector has underutilized infrastructure and talent that we plan to utilize.” Ridgeline co-founder Ryan Clinton said,“BlueShift raises the bar for sustainable industrial innovation, advancing domestic critical-mineral production while capturing carbon from seawater. At Ridgeline, we’re proud to back a team proving we can unlock vital resources and build a more resilient future.”

Combining proprietary membrane-free technology developed by the University of Michigan and Harvard University along with additive manufacturing elements and existing infrastructure, BlueShift’s innovative electro-chemical systems process alkaline industrial waste and seawater to isolate critical minerals. BlueShift intends to co-locate its projects next to coal plants that use seawater for direct cooling. The tech can extract minerals from the coal ash and CO2 from the sea in the form of limestone, which helps address the growing environmental issue of ocean acidification. It says its tech is 10 times more energy efficient than competing mineral extraction technologies.

BlueShift Avoids Environmental Harm

Like most traditional mining practices, the extraction of critical minerals and rare earth elements (REE) cause significant environmental damage, including ecosystem destruction, water pollution, and toxic waste production. Despite those negative aspects, several trillion dollar global industries depend on these raw materials to produce everything from steel and cosmetics to advanced battery technologies. In fact the demand for critical minerals for clean energy technologies is expected to triple by 2030. Adding to the challenge, China currently accounts for 70% of global REE extraction, 87% of global REE processing, and about two-thirds of the world’s processing and refining capacity for critical minerals. Domestic sources of these raw materials have become increasingly important for both US sustainable energy goals and national security.

In recognition of those challenges, the BlueShift team developed its electro-chemical systems to unlock resilient, rapidly scalable critical mineral supply chains. Past efforts at isolating these minerals from industrial waste have struggled to scale due to the high energy costs and intensive capital requirements associated with prevailing electro-chemical processes. By avoiding the use of previous materials or bipolar membranes, BlueShift’s technology also requires significantly less capital expenditures. Taken together, its technologies offer a low cost, energy efficient means of addressing ocean acidification through direct carbon dioxide removal from seawater. Its Boston Harbor pilot facility is expected to see a 30 times increase in total carbon dioxide removed annually. Patel says BlueShift plans to be able to produce one ton per year of nickel and rare earths from its pilot project by the second quarter of 2026.

“Meeting our climate goals is going to require low cost, large scale carbon dioxide removal. BlueShift’s electrochemical technology is a promising new solution to this problem, while its domestic production of critical minerals could contribute to resilient supply chains for clean-energy industries,” said David Wilson, the investment principal at the Massachusetts Clean Energy Center. “We’re delighted to be working with the team, as they build their company and pilot the technology in Massachusetts, and glad to have ConocoPhillips bringing its energy industry expertise and support.”

Companies that could help onshore the development of critical minerals could prove popular with investors, policymakers and buyers like battery manufacturers. BlueShift’s business model comprises multiple distinct revenue streams, including the sale of critical minerals such as nickel, REE products such as neodymium and dysprosium, carbon credits, and licensing and engineering packages to utilities, desalination plants, and others. The BlueShift team has already secured several suppliers of input materials for the extraction of critical minerals and REE from coal ash and olivine mining waste. Both inputs will be processed over the next three quarters as an initial go-to-market implementation of the company’s electro-chemical technology and carbon removal system.

Whether you have solar power or not, please complete our latest solar power survey.

Chip in a few dollars a month to help support independent cleantech coverage that helps to accelerate the cleantech revolution!

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy