H-E Parts International was recently renamed HEPI, which stands for Heavy Equipment Part International. The company is a global supplier of parts, remanufactured components, and equipment to the mining industry, covering both mobile equipment such as mining trucks but also fixed equipment such as mining crushers. IM Editorial Director Paul Moore recently sat down with HEPI Vice President South America, Javier Varela, and Global Marketing Director, Benjamin Bowlware, in Antofagasta for some insight into its current success and growth plans in Chile and the wider region.

Left to right: HEPI Global Marketing Director, Benjamin Bowlware, IM Editorial Director, Paul Moore, HEPI VP South America Javier Varela

Varela told IM: “We have two locations in Peru – on in Arequipa and one in Lima – the one in Lima was the first. Then in Chile we have a large facility in Antofagasta which is a new site opened in 2018. These facilities offer component repair for both surface mobile mining equipment as well as fixed crushers where we supply wear parts and service solutions. They also represent HEPI’s many different engineered product solutions for mining including rear wheel groups and electric drive motors for Komatsu and Caterpillar trucks. In Chile specifically, HEPI is also very strong in hydraulic solutions and hoses as well as lubrication, as well as operator cabin components.”

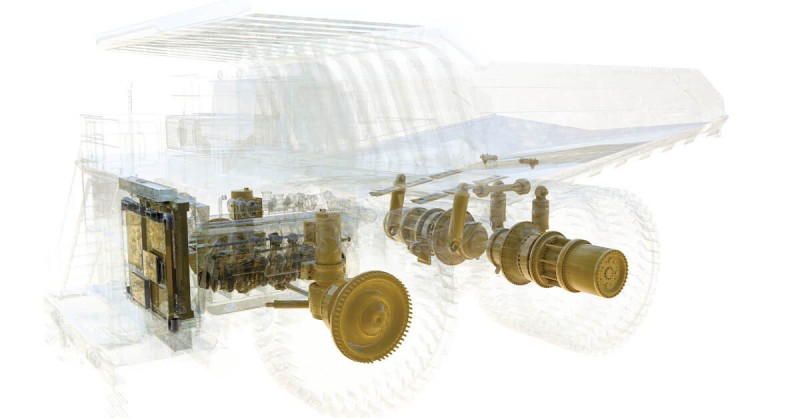

The Chilean facility is strategically located on Route 26 (Ruta 26), approximately 15 km from Antofagasta. It provided the Chilean division of HEPI with productive space twice the size of the previous property with the capabilities to triple the division’s current production levels. It houses a fully equipped component repair centre for mining equipment, components for the power train, diesel engines, crushing product lines, and other integral services for heavy mining equipment. The facility also offers parts for mining equipment and remanufactured components, hydraulic hoses and fittings, brakes for trucks and shovels, lubrication equipment, seats for operators, filters and services.

Varela pointed out that the two markets have important differences. In Peru, less than ten large mines cover over 90% of the market – whereas in Chile it is well over 20 mines. “About 80% of decisions for the parts and services we offer are made by procurement teams in the mining groups, especially for larger and higher CAPEX solutions; with 20% by daily operations and maintenance teams for spare parts – it just depends what it is and when they need it.”

So where is HEPI involved in the typical life of a mining truck? Bowlware: “There’s a point in the equipment life cycle – typically after the OEM warranty ends – when customers begin exploring alternatives. That’s where we step in. As a trusted aftermarket provider, we offer solutions that help maintain performance while supporting efforts to lower total cost of ownership.” Bowlware noted that the timing of this transition varies based on each customer’s maintenance strategy and major service milestones.

Varela: “We aim to be very present in the crucial aftermarket period and provide high performance and trusted solutions in the shortest possible timeframe. There are also many scenarios where our products and solutions last longer and are more robust, so it will allow the customer to increase their time to maintenance stoppages. We have a whole engineering team which in many cases have reverse engineered OEM solutions or components for the better.”

Growth and consolidation

H-E Parts, now HEPI, has been built up via organic growth but also the acquisition of a number of different brands and businesses in key mining markets like Australia and the Americas, which led to some offerings being stronger in some markets as well as not all solutions being offered in all markets. However, the company is now becoming more globalised, and there is a concerted effort to bring key solutions to multiple locations. For example, the cooling business, including mining truck radiators, was not previously active in South America but has now been rolled out in Peru, with Chile to follow. Long term, this process will mean a lot of legacy brands will disappear so that most solutions are now simply branded HEPI, to give customers more of an idea of the broad range of solutions offered by the company from cooling to engine reman, to wheel motors.

This identity evolution to HEPI took place in February 2025 and saw the company structure moving to four main divisions – HEPI – Mining Solutions; HEPI – Cooling Solutions; HEPI – Dom-Ex; and HEPI – Crushing Solutions.

Some of the more well known solution brands will become part of these divisions – Birrana  for example – which covers the design, manufacture and rebuild of brakes, final drives, differentials, axles and suspension systems for Caterpillar and Komatsu mobile mining equipment – will now come under the enhancements business of HEPI – Mining Solutions. These mobile mining enhancements and innovations are now available globally with the core business remanufacturing and improving rear wheel groups for Caterpillar and Komatsu mobile mining equipment. Proprietary technologies include a Control Fit wheel bearing assembly, which includes a flexible spacer and hardened spacer plus bearing design and specifications as well as bearing fit and preload adjustment.

for example – which covers the design, manufacture and rebuild of brakes, final drives, differentials, axles and suspension systems for Caterpillar and Komatsu mobile mining equipment – will now come under the enhancements business of HEPI – Mining Solutions. These mobile mining enhancements and innovations are now available globally with the core business remanufacturing and improving rear wheel groups for Caterpillar and Komatsu mobile mining equipment. Proprietary technologies include a Control Fit wheel bearing assembly, which includes a flexible spacer and hardened spacer plus bearing design and specifications as well as bearing fit and preload adjustment.

Varela told IM: “We take the OEM solution and make changes and enhancements so that the resuting solution is actually better performing that the original. We can apply the technology through a direct replacement of the motor in an exchange; sometimes the replacement motor we have been able acquire on the open market through our HEPI – Dom-Ex used parts business and recondition it. In other cases, we recondition the same motor that we take out – there are many possibilities. And the HEPI – Dom-Ex business is another that we are actively growing in South America.”

And expansion via acquisition is still ongoing. Most recently, HEPI acquired in late 2024 substantially all the assets of Brake Supply Inc, a North American leader in aftermarket components for heavy equipment but with the opportunity to bring that business to South America and other markets as well.

HEPI often gets contracts to overhaul multiple trucks in a fleet – in recent years for example, it has overhauled Cat 797F truck mechanical drive rear wheel groups for Minera Las Bambas’ fleet in Peru; plus it has a multi-year, major equipment overhaul contract with Codelco. The contract was awarded to HEPI for the rebuild of 23 Komatsu 930E diesel electric drive trucks and has been conducted through Rajo Inca, Codelco’s Salvador Division and fully managed by the HEPI team based in Antofagasta, Chile. The contract includes the initial inspection, disassembly, major component repair including proprietary enhancements, assembly, delivery, and commissioning. Most recently, the HEPI – Mining Solutions team in Peru completed HEPI’s first Komatsu 980E rebuild.

Bowlware said its pricing is competitive with OEM pricing but combined with the fact that the resulting performance can be improved in terms of longer service life, HEPI is often an attractive option. “Our products are built to meet or exceed OEM specifications, and in many cases, they’ve delivered substantially longer service life in the field. We’ve had customers report significantly extended run hours on our components compared to their OEM equivalents – especially in high-demand applications like wheel motors.”

Global strength also reflects the fact that HEPI is part of Hitachi Construction Machinery, having been acquired in 2016. And this brings its own synergies. Wear parts major Bradken and fleet management system provider Wenco are also HCM-owned, and the three companies have a very complementary offering. Bowlware: “Increasingly we are looking more at what we can do together. Hitachi Construction Machinery wants to be a global mining solutions provider across numerous areas. For us, being part of HCM certainly brings an extra recognition of value on the part of customers plus a feeling of security and financial stability. In Chile, we feel we have space to grow further, while maintaining the high performance of the technologies and solutions that we are known for.”

The post HEPI in mining – innovation not duplication appeared first on International Mining.