Hindalco Industries, a flagship company of the Aditya Birla Group, has made significant strides into the electric vehicle (EV) sector, focusing on manufacturing critical components rather than complete vehicles.

Key Developments in Hindalco’s EV Initiatives

1. EV Component Manufacturing Facility in Pune

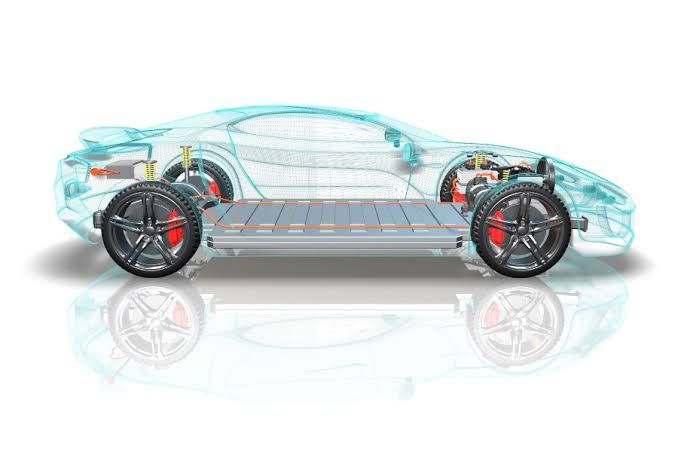

On April 25, 2025, Hindalco inaugurated a ₹500 crore EV component manufacturing facility in Chakan, Pune. This facility has successfully delivered 10,000 aluminium battery enclosures to Mahindra & Mahindra for their electric SUVs. These enclosures are designed to be lightweight and crash-resistant, aiming to reduce India’s reliance on imported EV components .

2. Battery Foil Manufacturing Plant in Odisha

Hindalco is investing ₹800 crore to establish a battery-grade aluminium foil manufacturing facility near Sambalpur, Odisha. Scheduled to commence operations by July 2025, the plant will initially produce 25,000 tonnes of aluminium foil annually. This foil is essential for lithium-ion and sodium-ion batteries, serving as a current collector in battery cells .

3. Investment in Copper Foil Production

As part of a broader ₹45,000 crore investment in its aluminium, copper, and specialty alumina businesses, Hindalco plans to establish India’s first copper foil manufacturing facility dedicated to EVs. Copper foil is a critical component in lithium-ion batteries, acting as the anode current collector .

4. Sustainability Initiatives Across Operations

In line with its commitment to sustainability, Hindalco is transitioning its internal logistics to electric vehicles across all its plants in India. For instance, at the Aditya Aluminium plant in Odisha, the company has introduced EVs for fly ash transport and established EV charging stations. This move aims to reduce 3,500 tonnes of CO₂ emissions and save ₹1.5 crore in freight costs .

Strategic Outlook

Hindalco’s ventures into EV component manufacturing and battery material production position it as a pivotal player in India’s EV supply chain. By focusing on the production of essential materials like aluminium and copper foils, the company is addressing critical needs in the EV industry, promoting self-reliance, and contributing to the nation’s sustainability goals.