Sign up for CleanTechnica’s Weekly Substack for Zach and Scott’s in-depth analyses and high level summaries, sign up for our daily newsletter, and/or follow us on Google News!

Recently, I had the opportunity to sit down with Simon Todd, PhD, geologist, expert in geothermal, founder of Causeway Energies, and Irishman, not necessarily in that order, to talk all aspects of geothermal. Despite being often far underground, it’s having a moment in the sun right now, hence a recent dozen part series on my part on the subject and this conversation with Simon. This is the lightly edited transcript of the first half of the conversation.

Michael Barnard [MB]: Hi, welcome back to Redefining Energy Tech. This episode is powered by TFIE Strategy, guiding investors toward climate-smart bets that will win in the real world and in the market. I’m your host, Michael Barnard, and my guest today is Simon Todd, Managing Director of Causeway Energies, Ph.D. in geology, and expert in geothermal energy. Welcome, Simon.

Simon Todd [ST]: Well, thanks, Michael. It’s good to be here. Many thanks for the invitation to participate in this nerdcast. I’m looking forward to it.

MB: As you know, I’ve finally gotten around to going deep on geothermal, and now I’ve got an opportunity—while it’s fresh in my mind—to talk to someone who actually knows what’s going on with heat. So I’m very pleased about that. But let’s start with Simon Todd. We’re nerds, and something I’ve learned is that other people actually like to know the people. So why don’t you start by talking about how you arrived where you are—because it’s a long and multi-country journey.

ST: Yeah, very good. Thank you for that. I’m Irish—born in Northern Ireland, in Belfast—grew up on the north coast. At thirteen, I started studying geology at school, thanks to one of those Mr. Chips–type teachers who was truly inspirational. The geology of the north coast of Ireland is fascinating—a really good place to study and grow up. That experience pushed me toward university to study geology as my primary subject. I went to the University of Bristol, encouraged by my mother to get “across the water,” as we said—out of troubled Northern Ireland at the time and into a different region and culture. I ended up studying to PhD level, as you mentioned, looking at rocks in southwest Ireland, in County Kerry—which is now my second favorite county in Ireland.

And that led me to work not only with people at the University of Bristol, but also with geologists at University College Dublin in Ireland. That connection is important to the story. After that, I joined BP—25-year career with that once amazing and continually interesting company. I was a geologist for the first phase of that, then moved onto a management executive track that took me up the greasy ladder, up the greasy pole to a certain extent—but also took me around the world, including coming to the United States over 20 years ago now. I led major parts of the business in the North Sea, deepwater Gulf of Mexico, Trinidad, onshore U.S., and experienced the wonders of scientific innovation being turned into brilliant engineering in very large major projects—including some black swan events.

I know you’re a keen fan of Flyvbjerg’s work, and I’ve got the scar tissue from those things. I left BP in 2014, and for the first few years I was mucking about with oil and gas rainbows—a bit of consultancy on process safety and operational integrity, which I learned a lot about at BP, for probably obvious reasons. Then, about seven years ago, I started saying to myself, right, I need to apply all of this skill to the energy transition. I liked the challenge, because I knew I was going to learn new stuff but also bring in the old stuff as well. From a personal perspective, geothermal was a bit of a sliding doors moment. I was appointed an adjunct professor at University College Dublin’s School of Earth Sciences in 2019.

There were still some people around who remembered me fondly from my first time there, and I visited with them just before COVID shut everything down. I said, look, this is very nice and we’re very proud of it and all the rest of it—but what can I do to help? And around the lunch table, they said: geothermal. They wanted me to use my location—or at least part-time location—in the U.S. to help understand what’s happening there with geothermal tech and what could be applied to the rather modest geothermal resources on the island of Ireland. So I turned to Dr. Google. I knew what geothermal was, but I launched myself onto a pretty steep learning curve. I ended up talking at conferences and so on pretty quickly, because most everybody was getting up the same curve.

And then, amongst that, myself and two other oil and gas industry colleagues founded Causeway Energies. We deliberately founded it in both Northern Ireland and the Republic of Ireland because we wanted it to be an all-Ireland approach, and we wanted to have feet in both the EU and post-Brexit UK. So that’s how I got here, Michael. Does that make sense?

MB: It does. And as I was saying, I helped found—and I’m continuing to drive forward—a company founded in Ireland to have EU access and UK access. So I get the impetus. But nerdiness—let’s talk heat, and let’s talk heat underground. Tell us, and tell me, about how much hotter it gets, why it gets hotter, how hot it gets—all those things.

ST: Yeah, brilliant. So, roundabout—the Earth’s core is around 6,000 degrees Celsius, right?

MB: For context, the Sun’s surface is 10,000 degrees, so it’s 60% the temperature of the sun.

ST: Yeah, it’s not too far, right. And temperature at the surface is anywhere from 5 to 30 degrees Celsius. The intervening rock layers include various parts of the core and the mantle, with a thin crust on top—particularly in continental regions. That heat is emanating out of the core as what we call a heat flux. Fortunately for us, rocks aren’t very conductive, so the flux is quite slow and gradual. That 6,000 to 10,000 degree temperature gradient is spread out across 5, 6, 7, or 8 kilometers of Earth’s structure in the shallow subsurface. What we see from boreholes is that in the first 10 to 15 meters, you get seasonal variation when you measure the temperature.

So there’s interaction with solar radiation, ambient temperature, and also groundwater moving through those shallow layers. Once you get to about 15 meters—sometimes a little deeper, sometimes a little shallower—you start to see the geothermal temperature increase gradually. In most continental areas, it’s around 25 degrees Celsius per kilometer. At that point, you’re out of that sort of interim neutral zone between what’s happening at the surface and what’s going on at depth, and you’re into a proper geothermal gradient. That temperature increase is due to the flux from the Earth’s core. The last thing I’d say about it is that the whole process is uneven—heterogeneous, we’d say. So at tectonic plate boundaries, places where the crust is stretched thin, or where there are hotspots and molten parts of the mantle have pushed up and pierced the surface, you get much higher gradients.

The geothermal gradients are much higher, and of course, you’ve got hot rocks and hot fluids pretty close to the surface—which, as we know, have formed the basis of conventional geothermal power.

MB: So let’s start there. Talk about conventional geothermal—what are the basics of that? Where is it? How economic is it? What are its characteristics? What are the useful things to know?

ST: It is restricted to these hot areas—along tectonic plate lines, volcanic hotspots. Classic areas, of course, include parts of the western United States, New Zealand, Southeast Asia—Indonesia is a good example. Iceland is probably the best example, with, I think, close to two-thirds of their electricity generated from geothermal. But it’s restricted because to do steam or flash steam turbine technology, you really need to be way over 200 degrees Celsius. Now, binary organic Rankine cycle turbines, where you’re using a lower vapor point or lower flash point fluid, do help a lot, and I’d still put most of that in the conventional geothermal category. For example, most of the Nevadan geothermal sites that have been around for 30 years—some of them—they’re binary organic Rankine cycle turbine fields.

The economics are helped because of the shallow nature of the temperature and the permeability of the steam. When you look at that in isolation, the economics look pretty good—especially in levelized cost studies like the Lazard ones. But it’s helped out by that heat-at-surface factor. I think that’s how I’d summarize conventional geothermal.

MB: Talk just a little bit more about the organic Rankine cycle, because that’s an interesting nerdy aside—and it keeps coming up. I think people are overstating it in other parts of geothermal, personally.

ST: Yeah, so there is a potential for overstatement—that’s right. With the organic Rankine cycle, the refrigerant in the heat exchanger flashes off at a lower temperature than water or steam, which allows you to use lower-temperature heat from the subsurface to generate work in the turbine, which in turn generates electricity. The potential overstatement comes from the fact that there’s no change to the fundamental thermodynamics—it’s still an inefficient way of generating electricity. So in terms of heat-to-power efficiency, you could be down at something like 15% of the heat being converted to electricity. And that, of course, impacts the economics, especially if you’re not doing anything with the 85% of the heat that’s not being used in that process.

So it does get projects by and make them economic—like those Nevadan ones—but it’s not a silver bullet by any means. The other thing to say is that there’s some interesting research going on around different refrigerants within the turbine cycle. And it was actually one of those projects that got me interested in supercritical or transcritical CO₂. I know you’ve made some comments about that, but it is a fascinating topic that led us to invest some time in the Carnot cycle version of it for a heat pump, working with the Southwest Research Institute in San Antonio, Texas. Can talk about that.

MB: Supercritical CO₂ works really well for decaffeinated coffee, works well as a refrigerant, and for dry cleaning. It’s great for basic heat exchange. But as soon as you’re putting supercritical CO₂ into a turbine that’s spinning rapidly—well, turbines like gas when they’re spinning rapidly, not supercritical fluids, which cause pitting and corrosion. We’ve been working on the materials science of supercritical CO₂ in electrical generation since, I think, 1946—that was the first trial. The U.S. Department of Energy has had research programs going since then. And it keeps coming up, keeps getting headlines. And like fusion, it never, ever gets to commercialization.

I have this red flag. If it’s been around for 80 years, and we’ve been trying it for 80 years and haven’t made it work—if nobody’s managed to make it work and make it commercially viable—it’s unlikely that it’s suddenly going to happen next year.

ST: It’s interesting. When I met with the Southwest Research Institute scientists—this would be three years ago now—they were quite proud of the work they’d been doing on a smaller turbine. They’ve built it and pilot tested it now. But when I mentioned the idea of exploring further the use of the same kind of phase cycle in a heat pump, they were really excited. They said, “We’re glad you’ve come—we’ve been wanting to do this for some time.” And the study did come out with an interesting set of insights that actually led us to apply for a patent for what we discovered.

But like your story, our story hasn’t progressed further because we decided to concentrate on proven tech and getting projects in the ground—literally—instead of trying to raise money for something that, while not totally blue sky and never going to happen like you described, Michael, is certainly going to take five or ten years to get anywhere close to commercial. And I don’t have enough time for that.

MB: And besides, Sanden already has a CO₂-based hot water heater that uses the supercritical aspects. There are commercial products in the market from Asia. As soon as you say that, you go, wait a minute.

ST: Yeah, that’s right.

MB: Okay, so back to underground. We’ve talked about it—so let’s focus on basic geothermal ground source heat pumps, the shallow stuff, just exchanging heat with the ground. Tell us about that, because it has a big reach. I discovered recently that China has something like 77 gigawatts of basic ground source geothermal, which doesn’t surprise me because all numbers from China are big—except for fuel cell vehicles. So tell us about ground source heat pumps.

ST: For ground source heat pumps, I actually prefer the term shallow geothermal because I think we sometimes confuse ourselves with the source of the heat. But let’s stick with ground source for this conversation. There are really two types of underground heat retrieval. The principal type is closed loop. Typically, a borehole is drilled to 150, maybe a little over 200 meters—usually about 6 inches or 150 millimeters in diameter. It’s very simple, almost agricultural. A high-density polyethylene tube is used—typically a quarter-inch U-tube run down into the well. Sometimes it’s a W-tube, so there are two loops going into the borehole. Heat is recovered via conduction. That tube, by the way, is grouted or cemented into the borehole—sometimes gravel-packed, but mostly bentonite grout or cemented in. So heat is gathered by conduction.

In closed-loop systems, the conduction comes from the rocks, through the cement, through the polyethylene, into the fluid—typically a water-glycol mix. That fluid is circulated around the loop in the borehole, and heat is extracted via a front-end heat exchanger on the heat pump. That heat is used to vaporize a very low vapor point refrigerant. The refrigerant is then compressed—adding extra electrical work, which increases both the heat and the temperature of the compressed gas. That heat is then exchanged to whatever the target is, whether it’s hot water or base heating. The cycle completes with the compressed gas expanding and returning to its original liquid form, and the heat pump cycle continues. The liquid in the loop returns to the borehole 3, 4, maybe 5 degrees cooler than before.

The idea is it warms up. What I’ve observed is that these shallow closed-loop systems work best—and are best designed—as seasonal systems, because that gives the geothermal resource a chance to recover temperature by conduction. Typically, when you see design profiles over 20 or 25 years, modeling the full-year performance of the heat pump, you’ll see little seasonal cycles in the exiting or entering water temperature within the loop. That’s the seasonal abstraction of heat followed by recharge. Now, there are other complexities we can get into, but that’s closed loop. Open loop is where you’re fortunate enough…

MB: Let’s just start with that one. I wasn’t surprised to find that I was wrong about something—I’ve been wrong about a lot of things. And I’m really glad I didn’t publish extensively on the stuff I was wrong about before investigating. But one of the things that was fascinating me is thermal storage in underground closed systems.

ST: Yeah.

MB: So you talked about extracting heat from the earth, but you can also extract “cold” from the earth—air quotes. So how does that work when it’s hot underground?

ST: That’s the next level of sophistication. I mentioned earlier that rocks aren’t very conductive, and that’s part of the reason why closed-loop systems have this thermal decline. You chill the immediate rocks around the borehole quite quickly—within hours or a day—and then that thermal aureole moves out fairly slowly. If you keep dragging heat out, it reaches what we call pseudo steady-state decline, where the profile drops a fraction of a degree—maybe 1 to 2 degrees per year—depending on the drawdown you’re exerting. In storage terms, these closed-loop borehole heat exchangers are actually advantaged by that conduction effect, because if you’re injecting heat into the boreholes instead of abstracting it, that heat doesn’t go very far.

It goes centimeters, meters, maybe up to 10 meters away from the borehole. And that allows proven technology around underground thermal energy storage to be a thing—and a thing we’re quite excited about. That thermal energy storage could come from solar thermal. So in the summer, when you don’t need the heat for winter demand, you take peak solar thermal heat and store it underground for recovery in the winter. And the round-trip efficiencies of this, Michael, are actually pretty good—better than 80%, maybe better than 90%.

MB: I had no idea the flux in rock was so low. I had assumed a higher flux—and I was wrong.

ST: Yeah, with conduction only, that’s absolutely the case. Of course, once you get into hydraulics, advection, and convection—it’s a different story.

MB: Let’s just test this. In a city like Chicago or Toronto—a city that has both winters and summers, with high cooling loads in summer and high heating loads in winter—this is a perfect round-trip setup. You dump heat down in the summertime and dump cold down in the winter, balancing it back and forth. You don’t deplete the resource; you’re actually storing cold for summer and storing heat for winter.

ST: Exactly right. It’s almost like a nirvana of circularity at work in those seasonal combinations and in climates like that, because that first shallow 200 meters or so sits at around 9 to 13 degrees Celsius. So it’s warm enough in the winter to add heat to the heat pump effectively, but also cool enough to act as a thermal sink for injecting waste heat from air conditioning or heat pumps in reverse. In actuality, it’s an effective heat sink for waste heat. And it’s also pretty tried and tested technology—in my view, and in many people’s views, completely underutilized.

MB: That’s one of the counterintuitive things. Anybody who’s been in a cave, a tunnel, a basement, a cellar—it’s colder down there, but only for a while. After a certain depth, it starts getting hotter. So down in that hundred-meter range, it’s 9 to 11 degrees, not 25 degrees. But just keep going, and it gets hotter and hotter. Yeah, so that’s one of the things.

ST: Some of the experts on this describe it really nicely. They say your coefficient of performance is a measure of efficiency for the heat pump—so if you’re getting a COP of four and a half for heating in the winter season, that’s excellent. And in quite a lot of environments, they even say you don’t need a heat pump at all—you’re getting the cooling for free. COPs over 10, with only the circulation pump using energy in that setting.

MB: Well, that’s an interesting one. Let’s just touch on that a little bit. The coefficient of performance is largely bounded by the difference between the heat source and the heat sink. So talk a little bit about that.

ST: Yeah, that’s right. The COP is largely controlled, as you say, by the difference between the temperature of the source heat you’re using and the output—or discharge—heat, which is technically called the sink. That temperature difference is a major factor in determining the coefficient of performance of a heat pump. You can think about it in quite simple terms: COP is the amount of heat delivered to the target, or the sink, divided by the amount of electrical work done—that’s the ratio. And if you think about it, the harder the heat pump has to work to lift lower and lower temperatures to the required high temperature, the lower the COP will be. So it’s quite easy to understand in layman’s terms.

There are other controls, particularly with special refrigerants like CO₂, that come in and offer different influences on the COP of the heat pump system. But that’s the main one, yeah.

MB: An air source heat pump, like the one on my balcony that I finally got installed last year—thankfully, given the Irish climate, which meant we didn’t need air conditioning—except the climate’s changing, I don’t know if you’ve heard. That air source heat pump in the winter has a lower coefficient of performance, and the colder it gets, the worse it performs. At minus 20 degrees Celsius, it might be around 1.2 COP. But a ground source heat pump maintains a high coefficient of performance all year round.

ST: We did a really interesting feasibility study for a client last year. It was a one-and-a-half megawatt demand for foodstuff and chemical storage tanks—to heat them. It was in Liverpool, England. The study gave us a great opportunity to compare air source with water source from the River Mersey, in that case, with a shallow geothermal model—open loop, which we can get to—not closed loop, and a somewhat deeper geothermal source which was, instead of the 11 or 12 degrees from shallow, more like 18 or 19, maybe 20 degrees Celsius. We worked with half a dozen different European industrial heat pump manufacturers who gave us really good numbers and performance data for these different source temperature ranges and how the heat pumps perform.

All natural refrigerants—ammonia, pentane I think it was, or yeah, pentane—and CO₂ was in there as well. Much to our surprise, the numbers were pretty fascinating. The water source beat the air source just marginally because the capital for all the pipework to draw water from the river was obviously higher. However, what we observed—which surprised me—was that the river temperature actually varies a lot seasonally. In fact, in that geography, it’s only a fraction of a degree different from the ambient air. The average seasonal COP for air in Liverpool worked out to about 2.9, if my memory serves me correctly—quite low in the winter, as you said, Michael, and a little higher in the summer.

Same with the river—only marginally better than the shallow geothermal with that 11 or 12 degree constant. It beat air source and water source economically. The water source surprised me, but the reason was that all the capex for those big 12-inch pipes was actually more than drilling some shallow boreholes. And then guess what—the one where we had the deeper geothermal at 500 to 700 meters was the winner economically in the trade-off. That extra temperature, affecting the COP and therefore the amount of electricity used, really makes a difference. The operational electricity cost savings against the benchmark more than adequately paid for the incremental capex in that case.

In fact, a three-year payback from that very diligent feasibility study really crystallized the opportunity for me in these ground source or shallow geothermal heat pump systems.

MB: Let’s tease apart one more thing—because “megawatt,” you used 5 megawatt, and that is such an overused metric, especially in Europe where they use it for natural gas, which I think is one of the stupidest things I’ve ever heard. And now they’re using it for hydrogen, which is even stupider, because hydrogen isn’t an energy carrier—it’s an industrial feedstock. They’re just pretending it’s going to be an energy carrier. So when we say 5 megawatt for a heat pump, what do we mean? Is that the electricity in? The heat out? How should we think of that?

ST: I’m always talking about heat out—that is, thermal energy delivered. And talking in megawatt-hours, or megawatts if we’re on par, allows us to correlate with the electricity used, of course. I’m actually a bit more comfortable converting cubic meters or cubic feet of gas into kilowatt-hours to match up that equation. When we talk about competitive economics, it’s useful to have the same unit when comparing gas combustion energy to electric.

MB: I just prefer if we stuck with gigajoules for some of that stuff. Call me a nerd. But let’s tear that apart one more time. If I understand correctly, let’s pretend we have a ground source heat pump at 500 meters for an industrial application. You end up with a coefficient of performance of five. You have five megawatts of heat out—that means you’re using one megawatt of electricity.

ST: Correct.

MB: And so that’s the big win is you can ground source. You multiply the electricity by more. You’re using work from the electricity to extract heat from underground.

ST: Yeah, uplift it. Perfect.

MB: Okay, next one. Then we’ve got moderate depth and aquifer—do you want to put them together? Do you want to tear them apart? What do you want to do?

ST: Let’s go open loop first and then go a little deeper. In open loop systems, hydraulic fluid flow comes into the equation, and depending on the permeability, that controls the productivity coming out of the rock. It’s generally much faster conduction. What we find with shallow systems is that if we’re in a constrained urban environment where there isn’t enough room for all of those closed-loop boreholes, but we have a shallow aquifer that’s perfectly suitable as an open loop source, then we use it. Other than that, it’s the same thing—except instead of closed-loop circulation, you’re circulating open loop, meaning you’ve got an abstraction.

That takes water out of the aquifer, brings it up to the heat exchanger to extract some heat, then the water goes back down underground into an injector well—typically spaced a little distance away from the abstraction well to limit or avoid both hydraulic and thermal interference in the system. Having said that, like we talked about with borehole thermal energy storage, aquifer thermal energy storage is a thing as well. You can reverse the process. In fact, there are now thousands of aquifer thermal energy storage applications in Belgium and the Netherlands. These are hundreds-of-kilowatt-scale systems, commercial building–scale systems. I think the number in the UK is 15. The number on the island of Ireland is zip, zero, nada.

And so again, it’s like—come on, this is a technology diffusion opportunity that really ought to be happening.

MB: I have a nerdy question about geology. I’m familiar with the geology of the Biscayne Aquifer because I’ve studied it—it’s caught between sea level rise and the increasing brackishness of the big swamp down there. Add in Superfund sites and sprawling subdivisions without sewage systems, just pits—it’s a recipe for disaster. And it’s the source of fresh water for southern Florida. So it’s dead. But that aquifer is a limestone sponge. Having studied enough about fracking, I know they’re effectively creating fracked areas in shale and injecting quartz pebbles to keep the fractures open, to increase the flow rate and allow flow.

I always have this visual image stuck in my head about the aquifers we’re talking about in the Netherlands. Are they permeable rock sponges, or are they little bubbles of water underground? What’s the actual geology of them?

ST: They’re rock sponges. The rocks have microscopic to barely visible pores in them, and those pores are connected. This is the geothermal distinction between porosity and permeability. The porosity holds the water, but you need the permeability—the connection between those pores—in order for it to flow. That’s the same in the oil field, of course, until the advent of hydraulic stimulation, as we like to say, to avoid the word beginning with “f,” which creates its own engineered reservoir allowing the fluids—be it oil or gas in the case of petroleum—to flow. Those Florida limestones, I think they’re Cretaceous, coexisting with the dinosaurs, likely have a mixture of sponge-like porosity and maybe some natural fractures as well.

MB: How do you measure permeability? Just as we talk, what’s considered good permeability for an underground thermal aquifer?

ST: I need to be careful here not to mix up oil and gas terms with hydrogeological terms—different viscosities, among other things. My legacy training is in oil and gas. For conventional reservoirs, we typically measure permeability in darcys or millidarcys. Tight is less than 10 millidarcys, and a really good day at the office is one darcy for oil and gas reservoirs. That applies more to oil; gas, of course, being less viscous, it’s less of an issue. In geothermal speak—particularly shallow geothermal—it’s a different context.

MB: You can’t get away with introducing a Jane Austen term without defining the Jane Austen term.

ST: I’ll get back to you on that one, Michael. It’s an equation of hydraulic flow, depending on the pressure gradient and the actual permeability of the pore space. It’s been around since Sir Darcy’s time—a different Darcy than the one that sprung to your mind.

MB: One would assume.

ST: Yeah.

MB: Okay, so back to geothermal reservoirs or aquifers. What’s the millidarcys or darcys.

ST: Yeah.

MB: So I’m now picturing Colin Firth in a wet shirt.

ST: That’s right. Emerging from the standing body of water—that’s a useful thermal energy source as well.

MB: Well, I’ve just made geothermal a lot more interesting to a lot more people.

ST: That’s good to hear. You’ve put me way off track from what I was thinking about. So, open geothermals—if we stay with shallow for the time being, what we’re observing is that rocks with hundreds of millidarcy permeability are pretty good aquifer producers, capable of supporting powerful open-loop thermal abstraction.

MB: Does the darcy equation include viscosity?

ST: Yeah, it does.

MB: So in other words, the same size of fractures would be higher darcys for gas, medium darcys for water, and lower darcys for oil.

ST: And again, without wishing to get too nerdy, geothermal has an advantage because typically it’s a single-phase flow—it’s water. Whereas in oil and gas, the relative permeability of gas and water, or gas and oil, is different, and that can cause problems with oil movement when there are permeability differences between the two phases. In geothermal, we don’t necessarily have that problem.

MB: We won’t get too distracted by this, but it’s now happening in the Permian Basin in the shale region. They’ve tapped out the best sites, so the proportion of gas and water in the mixtures for any given underground stimulated region is now much different than it was. That’s causing very different economics. Right now, the Energy Information Administration projects 250,000 to 300,000 more barrels per day. I think it’s going to go down—not only because of that, but also because of the international decline in oil prices. But let’s not get distracted by that.

ST: It’s very easy. I agree with you—I think the oil price decline will be more significant than the subsurface piece. Although I have read statements from Permian CEOs saying they’re expecting that within the next four or five years.

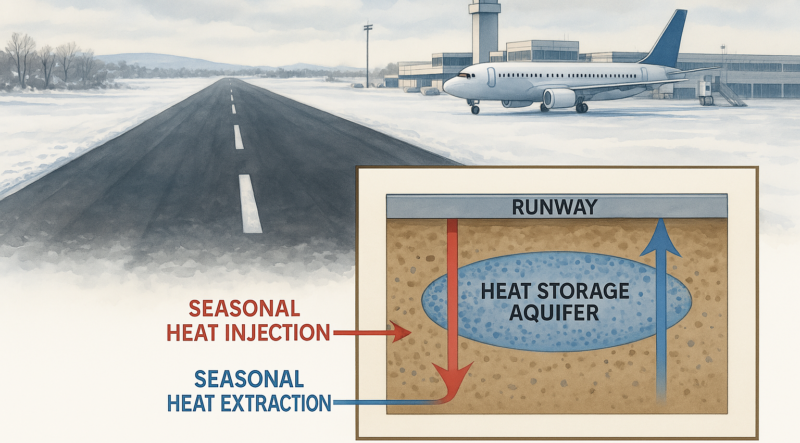

MB: I’m just less bullish than they are on the subject—or maybe I’m more bearish, or maybe I’m more bullish because I want that to go down since I’m on the other side of the equation. But back to aquifer geothermal: great permeability, medium viscosity, simpler fluids, and it allows heat storage. My favorite story about that is the airport, possibly in the Netherlands, possibly somewhere else. The Netherlands does get snow, and it uses an underground aquifer that’s heated up all summer, then used to clear runways of snow and ice and provide heat all winter long.

ST: Yes. And those airports, Michael, are among the biggest examples of shallow geothermal systems. I had a brief look at Dublin Airport Terminal 2 and spoke with the team there. They’ve actually started a project now, and just one terminal has a 25-megawatt heating and cooling load. Some of it’s synchronous—it’s a glass building, so during parts of the year they’re heating the north side while cooling the south side. It’s a perfect opportunity to have circularity in terms of heat and cool storage.

MB: Okay, we’ve got aquifers, we’ve got open loop. This is probably an extremist position, but I think the only valuable thing that came out of fracking—or stimulation, sorry I used the F word—is directional drilling. That has advantages. Personally, I think it’s especially useful for geothermal, where you can have an aquifer that’s a kilometer or two away sideways, and you can reach it. You can also access two different parts of it from the same pad, and I think that’s advantageous. Do you want to talk about directional drilling? You actually lived through the fracking innovation boom after Gerald Ford started investing in 1974, following the oil crisis. So tell us about directional drilling and why it’s so revolutionary.

ST: My first experiences as a professional were actually with the first subsea horizontal wells in the North Sea, in a little development called the Sarris. We also did horizontal wells in a field I was the development geologist for, called Andrew, after Scotland’s patron saint. That was, again, horizontal wells. In both cases, there were two reasons we went horizontal. One was that we were interested in staying within a particular zone. In the Sarris field, it was about staying high in the reservoir, away from the underlying aquifer beneath the oil. In the Andrew field, we wanted to have our horizontal wells perfectly placed within a 20-meter-high oil column that had a gas cap above it and a very active aquifer below it.

And so the placement of the horizontal well was to maximize oil production and minimize ingress of gas from above and water from below. That technology has since been applied in different ways, but let’s start with how.

MB: How do they turn a drill head 90 degrees underground?

ST: Magic. So instead of the drill string rotating, it’s pushed and pulled, and there’s an independent drill bit with a mud motor at the bottom of the drill string. That drill string and motor have a bunch of sensory equipment on them that can not only measure the position of the bottom of the hole in three dimensions but also record formation information, mud temperature information. The wonder of that is the information is pulsed back in the mud that’s circulating around the drill string and the borehole.

Which, 30 years later, still fascinates me—that you get real-time data on the location of your borehole, and then you have these masterful, somewhat artful directional drillers who use this information and play around with the torque and the load on the bit to adjust. There’s a somewhat torsional desire of the bit to turn to the right because of the rotation, and they use all of that manipulation to steer the drill bit and its driving motor in the desired direction. As I say, some parts of the oilfield still amaze me, even many decades later, with what has been accomplished.

Whether you have solar power or not, please complete our latest solar power survey.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy