Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

Last Updated on: 28th March 2025, 09:37 pm

EV buyers around the globe have made it clear that the bloom is off the rose of the Tesla brand, but zero-emission cars are not the only product under the corporate umbrella of the famous logo that resembles lady parts. Stationary energy storage is a big part of Tesla’s business, and competitive new technologies in that space are beginning to surge into the market just as the company lays plans to increase its Megapack output in the US.

The Long-Duration Energy Storage Factor

Lithium-ion batteries, such as the ones marketed by Tesla, have proven to be the workhorses of the renewable energy transition. In addition to their use in EVs, Li-ion technology fits the bill for stationary, utility-scale battery arrays that serve daily grid balancing tasks or provide emergency power when needed.

Li-ion energy storage systems last for a handful of hours, with around four hours being typical. That’s all well and good for now, but grid planners advise that diurnal (full day) energy storage technologies of 10 or more hours will be needed in the future, when the nation’s electricity profile is saturated with intermittent wind and solar resources.

The US Department of Energy has also been scouting for long duration energy storage technologies that can last for days, weeks or even whole seasons, and battery innovators have been responding to the call.

One Long-Duration Energy Storage System To Rule Them All

One among many long-duration energy storage innovations to surface is an iron-sodium formula developed by the US startup Inlyte. According to the company, their new battery can be deployed economically for shorter cycles of 4–10 hours, and it can also provide long-duration service of 24 hours or more.

Earlier this week, Inlyte announced a major acceleration of its manufacturing timeline, under a new Memorandum of Understanding with the longstanding Swiss battery manufacturer HORIEN Salt Battery Solutions (formerly FZSoNick).

“By joining forces with HORIEN, we gain access to world-class manufacturing expertise and established industry relationships,” explains Inlyte CEO and founder Antonio Baclig. “This will help us speed delivery of our breakthrough battery technology that combines the efficiency of lithium-ion batteries with the low-cost needed for long duration energy storage.”

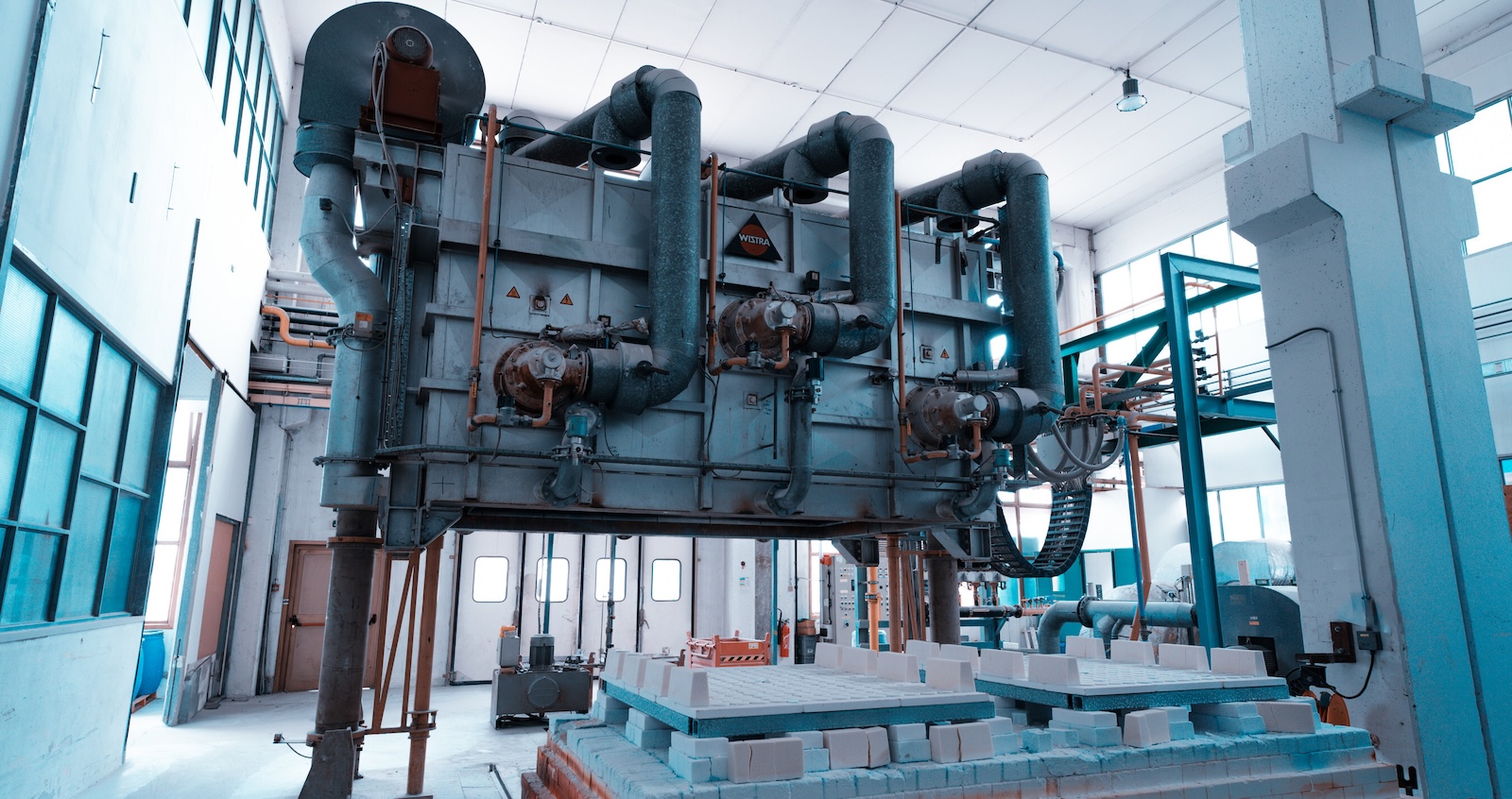

Inlyte has already proven its technology at its pilot plant in the UK, paving the way for the construction of the new “Inlyte Factory 1” in the US. The plan is to replicate HORIEN’s existing battery manufacturing system while integrating Inlyte’s iron-sodium technology.

Salt Batteries Are (Finally) Here

Salt batteries have crossed the CleanTechnica radar since the early 2000’s, the attraction being the opportunity to leverage inexpensive, abundant, and non-toxic materials that can be acquired through domestic supply chains (see more sodium battery background here).

There being no such thing as a free lunch, engineering efficiency and durability into sodium batteries has been a years-long journey, but some researchers have cracked the code. That includes Inlyte, which reported a key breakthrough in December. Following a testing period of more than 12 months, the company announced that its energy storage technology lasted for more than 700 cycles without losing capacity, while achieving 90% roundtrip efficiency.

“These results, representing over a year of testing, project a battery life of at least 7,000 cycles or 20 years — matching the proven performance of traditional sodium nickel chloride batteries, but at a fraction of the cost,” Inlyte noted.

A Decades-Long Leg Up For Long-Duration Energy Storage

Although Inlyte launched just a few years ago, in 2021, the company has availed itself of a decades-long energy storage knowledge base. In addition to the new MOU with HORIEN, Inlyte acquired the UK firm Beta Research in 2022.

As described by Inlyte, Beta Research is the home of a research team credited with developing the original sodium metal halide battery in the late 20th century, later bringing it up to commercial manufacturing capacity “on multiple continents.”

“Beta Research’s fully-functioning pilot production line, with 30,000 square feet of manufacturing and testing facilities, allows Inlyte to immediately go-to-market with pilot projects once the optimized design is complete,” Inlyte notes.

Energy Storage Manufacturers Heart Texas

Inlyte expects to have its US factory up and running in 2027, which is interesting in the context of current federal energy policy. The somewhat erratic Commander-in-Chief who occupies the White House has hatched a new “American Energy Dominance” plan that fails to take advantage of the most abundant and readily accessible energy resources in the US — namely, wind and solar power. Adding insult to injury, the Trump government has blocked renewable energy permits and is in the process of “reviewing” funds for long-duration energy storage projects previously committed by the Biden administration.

Nevertheless, Inlyte is confident that its US manufacturing plans are on track, with production beginning in 2027.

The company has not disclosed the location of the new factory yet. Any guesses? Texas, maybe? Despite the red-state rhetoric of Republican lawmakers in Texas, the business-friendly state just can’t resist the allure of cleantech enterprises, including energy storage ones.

Take Tesla, for example. The company launched with its feet firmly planted in California, but in recent years, Tesla has linked its manufacturing fortunes to Texas.

In the latest news on that score, earlier this month the Texas news organization Covering Katy News reported that the City Council of Brookshire, Texas, and the Waller County Commissioners Court approved a tax abatement to smooth the way for Tesla to bring a new Megapack factory to the Empire West industrial park near the City of Katy.

Make Room For Iron-Sodium Batteries

CKN also noted that the new Megapack factory will occupy a building constructed under an on-spec program that Waller County launched back in 2010. Apparently, the commissioners are satisfied with the program’s ability to attract tenants and their investment dollars, too. Plans are already in the works for the further expansion of Empire West.

What do you think, will Megapacks meet with customer resistance as the grip of Tesla CEO Elon Musk tightens on the reins of the federal government? His “DOGE” team has already disrupted key services at multiple federal agencies. Toppling them altogether is the next step.

My guess is that brand reputation will not be a factor in Megapack sales, no matter what Musk says or does. Megapack buyers are focused squarely on the bottom line, unlike individual car buyers who can easily react to the unforced damage to the Tesla brand by simply choosing another car.

Nope. The real threat to Megapack sales will come from long-duration startups like Inlyte as well as global battery storage leaders like CATL.

Photo (cropped): A long-duration energy storage startup is laying plans to manufacture its new iron-sodium battery in the US, presenting a new challenge to Tesla’s Megapack business (courtesy of Inlyte).

Whether you have solar power or not, please complete our latest solar power survey.

Chip in a few dollars a month to help support independent cleantech coverage that helps to accelerate the cleantech revolution!

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy