Sign up for CleanTechnica’s Weekly Substack for Zach and Scott’s in-depth analyses and high level summaries, sign up for our daily newsletter, and/or follow us on Google News!

The global solar industry is beginning to coalesce around tandem perovskite cells as the Next Big Thing to chase fossil fuels out of the power generation field. One market-ready approach involves pairing perovskite film with durable silicon. Following close on its heels is a more lightweight, flexible version based on thin film CIGS technology.

Perovskite Solar Cells Are Coming For Your Fossil Fuels

The naturally occurring mineral perovskite is the inspiration behind perovskite solar cells. Synthetic perovskite crystals can be lab-grown, offering a relatively inexpensive alternative to conventional solar cells made of silicon. There being no such thing as a free lunch, though, perovskite solar cells are fragile (see more perovskite background here).

Pairing perovskite with silicon in a tandem solar cell is one workaround that is already emerging as a pathway to commercial production. Earlier this week, for example, earlier this week the leading Chinese solar manufacturer Trinasolar announced that it will manufacture tandem silicon-perovskite solar cells in China, under an exclusive licensing deal with the UK perovskite innovator Oxford PV.

The CIGS pathway results in a lower solar conversion efficiency than tandem silicon-perovskite solar cells, which have reached as high as 34.6%. However, flexible CIGS solar cells offer an application advantage. Due to their light weight and flexibility, CIGS-perovskite solar cells can fit curved surfaces and lend themselves to a wider range of uses than their heavier, more rigid silicon-based counterparts.

Solving The Perovskite Solar Cell Problem With CIGS

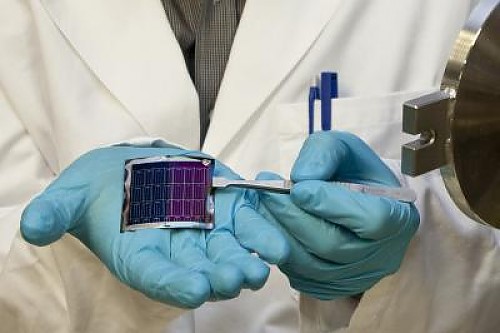

The CIGS solar cell formula is a thin, flexible film consisting of copper, indium, gallium, and selenium. At first glance it seems like a perfect match for thin films of perovskite solar cells. However, obstacles towards commercial applications abound, including the complex manufacturing systems required of CIGS technology.

A research team at the Korea Institute of Energy Research is among those closing in on the solution. In their new paper, “Flexible and lightweight perovskite/Cu(In,Ga)Se2 tandem solar cells,” the team describes how they developed a new manufacturing process while resolving other challenges related to the hookup between CIGS and perovskites.

On the manufacturing side, the KIER team demonstrated that a commonly used “lift-off” process can be deployed over a wide area, helping to reduce fabrication costs. They used a glass substrate beneath the flexible polyimide film used in conventional CIGS solar cell fabrication. As described by the researchers, the glass is more stable than polyimide alone, and it provides for a more uniform deposition of the solar materials.

The Perovskite Difference: Highest Ever CIGS Conversion Efficiency

The KIER team ultimately achieved a respectable 23.64% solar conversion efficiency for their CIGS-perovskite solar cell, described as “the highest recorded efficiency among flexible perovskite/CIGS tandem solar cells reported to date.”

That’s a significant jump up from the previous record for this type of solar cell, which KIER puts at 18.1%.

One key to the improvement was the combination of glass and polyimide for the substrate. By itself, glass enables potassium to diffuse into the CIGS layer, inhibiting solar conversion efficiency. The researchers surmised, correctly, that the polyimide layer would help prevent the leaching.

“When applied to the solar cell fabrication process, this approach effectively reduced defects in the CIGS light-absorbing layer,” KIER explains.

Look Out, Fossil Fuels

KIER also notes that its flexible perovskite solar cells retained 97.7% of their initial efficiency after undergoing a stress test of 100,000 bending cycles, an important consideration if the film is to be used in a variety of curved surface applications including building surfaces and solar-enabled EVs, for example.

The light weight of the new solar cells is a particularly significant advantage for electric mobility applications, where excess weight can reduce battery range. Dr. Kihwan Kim of KIER, who served as the principal investigator of the study, noted that his team’s CIGS-perovskite solar cells achieved a power-to- weight ratio of about 10 times that of silicon-perovskite solar cells.

“By advancing large-area fabrication processes and improving stability, we aim to strengthen the competitiveness of related industries and significantly contribute to the expansion of renewable energy adoption,” Kim emphasized.

Perovskite Solar Cells Are Here

While the R&D work is ongoing, perovskite solar cells are already surging into the market, with China in the lead. The licensing agreement between Trinasolar and Oxford PV is one example. Another is example UtmoLight, the solar branch of the firm SVOLT Energy Technology, which has been fine tuning a large-area fabrication method for its glass-encased perovskite solar cells.

The company recently reported 20.5% conversion efficiency for its mini-modules, which measure 63.98 cm2. “This indicates that China has mastered the core technology in the field of perovskite solar modules and it is only a matter of time before the country achieving mass production,” UtmoLight observed.

Sure enough, in February PV Magazine reported that UtmoLight has hit the go button on a new factory that will eventually ramp up to 1.8 million modules yearly. “In pilot production in November 2024, UtmoLight achieved a record 450 W power output with 16.1% efficiency on a 2.8m² perovskite module, PV Magazine previously reported, noting that the company anticipated achieving 20% efficiency at the start of mass production.

None of this is good news for fossil fuel stakeholders here in the US. The thin-skinned, dictator-adjacent Commander-in-Chief who occupies the White House has bent over backwards to fulfill whatever promises he made to his well-heeled donors in the fossil energy business, but the hits keep on coming.

“The cost of clean power technologies such as wind, solar and battery technologies are expected to fall further by 2-11% in 2025, breaking last year’s record,” BloombergNEF reported in February, crediting China’s manufacturing sector with pushing costs down globally.

“BNEF still expects the levelized cost of electricity for clean technologies to fall 22-49% by 2035,” BNEF added, emphasizing that trade barriers will not stop clean tech costs from dropping.

Although Trump killed practically the entire US offshore wind industry with a swipe of his pen, there is little he can do to stop the demand for clean kilowatts from solar energy in the US, which overseas investors are eager to feed. Perovskite solar cells or not, solar power is now a mainstream feature of the US energy landscape.

If coal stakeholders in the US are depending on data center energy demand for a lifeline, they will have to compete against solar and onshore wind as well as gas and nuclear. For that matter, geothermal energy will also be a force to be reckoned with. Hold on to your hats…

Photo: Researchers have combined flexible, lightweight CIGS solar technology with perovskite solar cells to achieve a new record in solar conversion efficiency (courtesy of Empa via CleanTechnica archive)

Whether you have solar power or not, please complete our latest solar power survey.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy