Perkins says it is showcasing a broad range of solutions at bauma in Munich, Germany, this week, each designed to solve customers’ problems as they navigate the evolving energy landscape.

At the show, Perkins will exhibit an expanded lineup of power systems, services and technologies that, it says, enable OEMs to build machines engineered for efficiency, productivity and fuel flexibility. Perkins is showing a range of new:

- Fuel-flexible optimised internal combustion engines;

- Hybrid solutions to optimise efficiency;

- Alternative fuel power systems to deliver long-term flexibility for the user;

- Electrification offerings for zero-exhaust emissions;

- Digital services to connect and provide condition monitoring data to customers; and

- Life cycle solutions to keep engines operating at their optimum productivity.

“Partnerships promote progress,” Jaz Gill, VP, Global Sales, Marketing, Service and Parts, says. “We’re a trusted partner who knows the industry inside out and truly understands the needs of customers. Their goals inspire us to innovate, which is why we work hand in hand with them to ensure their business success, today and tomorrow.

“There’s a lot of talk about where the industry is headed, but our focus is on addressing challenges and creating new opportunities for our customers right now. Whether it’s optimised internal combustion, a hybrid solution or full electrification, our team of expert engineers are focused on providing power systems that are built to perform and integration services that reduce the development timescale for our customers.”

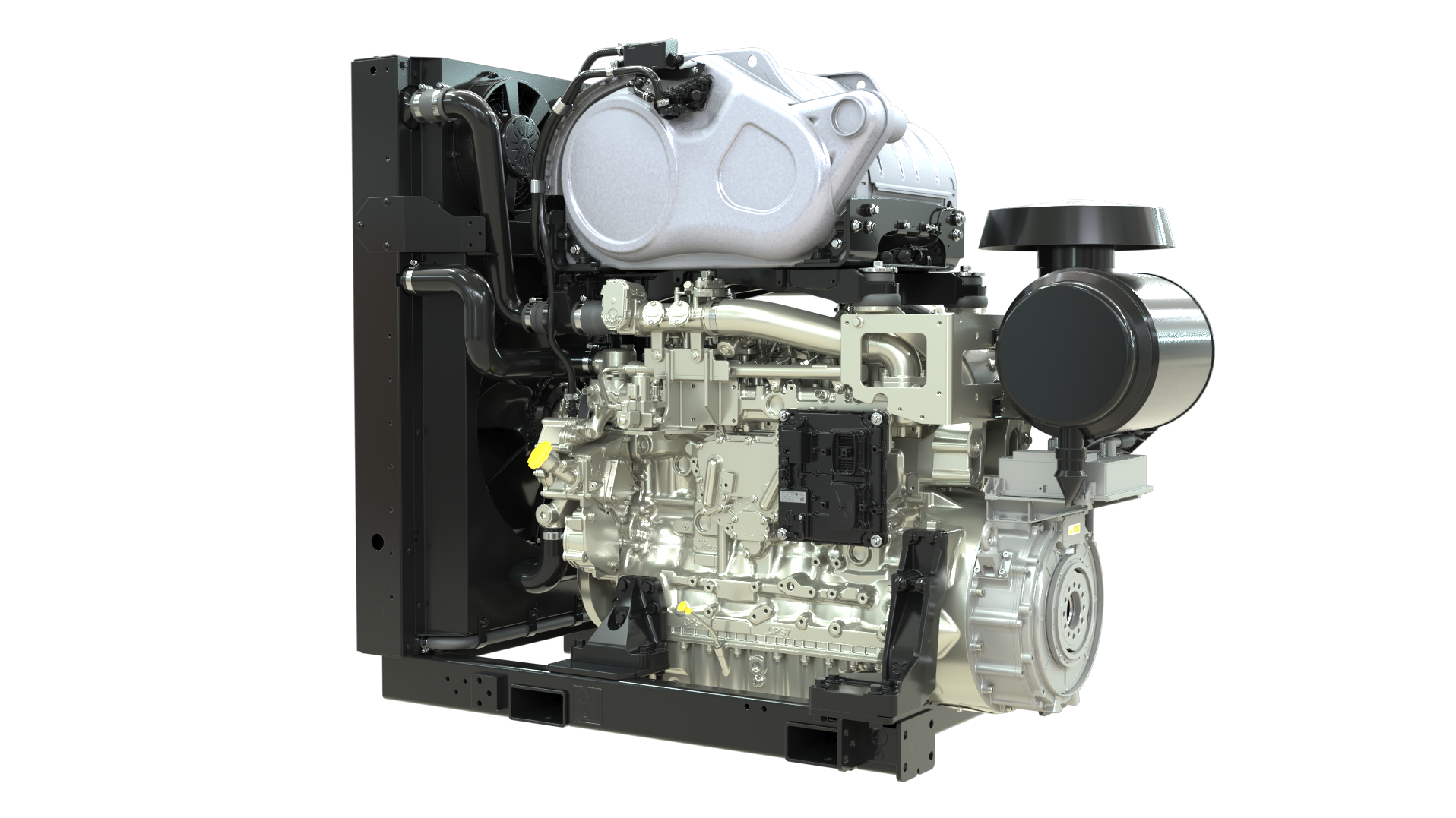

Available in 2026, the Perkins® 2600 Series engine platform is designed to meet the demands of construction and many other off-road, heavy-duty applications, the company says. The new 13-litre diesel engine platform achieves best-in-class power density, torque, fuel efficiency and productivity and extends Perkins’ leadership in high-performing, mid-sized engines with eight power ratings from 340 to 515 kW, offering up to 3,200 Nm of peak torque, it claims. Industrial open power units configured with engine-mounted aftertreatment and cooling packs will also be available to reduce installation and validation costs for OEMs.

The 2600 Series will meet the emissions standards of highly regulated territories, such as EU Stage V, US EPA Tier 4 Final, China Nonroad Stage IV, Korea Stage V, and Japan 2014, with models available for less regulated territories.

By modularising and eliminating components, its architecture is space-protected to accommodate configuration adjustments anticipated for future tiers of emission standards in the US and EU without relocating customer connection points, Perkins says. The 2600 Series engine platform also enables the use of renewable liquid fuels such as 100% hydrotreated vegetable oil (HVO), up to B20 for models with aftertreatment and B100 for models without aftertreatment1.

Perkins has also developed a comprehensive connectivity and condition monitoring solution to meet customers’ requirements and deliver measurable benefits to OEMs and operators, it says.

A telematics data sharing API is available for OEMs to share engine data from pre-existing OEM telematics systems, supporting equipment owners with enriched advanced analytics from the engine, supported by condition monitoring and insights that are sent to the customer’s engine support ecosystem.

Gill explains: “Seamlessly linking to customers’ equipment, Perkins connectivity solutions improve operational control. Whether monitoring performance or optimising efficiency, the real-time insights and proactive support available from the Perkins distribution network will minimise downtime through faster service response times and an increased first-time fix rate, as well as significantly reduced costs.”

The importance of protecting your engine investment for a lifetime is a key message at bauma, with an interactive display on the benefits of register, maintain, extend and replace. Together, these four actions optimise engine performance throughout its entire life cycle. “This approach enables our customers to prevent downtime and reduce the total cost of engine ownership, all while ensuring their worksites run efficiently and effectively,” adds Gill.

Perkins’ growing advanced power portfolio welcomes the addition of a new battery-electric power unit technical demonstrator, shown for the first time at bauma 2025. Shown in a pipe fusion machine, the plug and play battery-electric power unit is designed to enable off-highway OEMs to seamlessly transition from diesel to a battery electric powertrain, it says.

“We’re actively helping customers navigate the shift in power system requirements, with a range of advanced power systems including electric, diesel-electric and alternative fuel compatible engines,” says Gill.

“When it comes to the innovative fully integrated battery electric power unit, it can be ‘dropped in’ to a machine to replace a diesel engine. The system consists of a Perkins battery along with inverters, motors and on-board chargers – all packaged up into a compact drop-in system to support seamless transition from diesel to electric for our customers looking to make that move.”

The Perkins battery-electric power unit has been put to the test in a McElroy TracStar® 900i pipe fusion machine as a commercial demonstrator; with the battery-electric power unit replacing a 3.6 litre 904 Series diesel engine. The power unit’s compact design enabled the seamless transition from diesel engine to electric, with the power unit fitting within the same chassis space and having the same mechanical connection and electrical interface points as the 3.6 litre diesel engine power unit it replaced.

Gill continues: “This is a fully integrated battery drop-in solution, reducing the need for OEMs to invest in costly engineering and design projects and allowing them to electrify their machinery quickly and cost-effectively, without sacrificing performance. I’d encourage anyone considering the move towards electrification to come and talk to us about this drop-in solution which can deliver a faster return on investment, while providing the owner / operator with a low maintenance, cost-effective power solution.”

Project Coeus sees Perkins partner with e-powertrain specialists Equipmake and Loughborough University’s Wolfson School of Mechanical, Electrical and Manufacturing Engineering, to develop an innovative, advanced configurable-fuel drop-in hybrid power unit, as a direct replacement for a diesel engine.

The four fuels selected for inclusion in Project Coeus – ethanol, methanol, bio-methane and hydrogen – have one characteristic in common: they are all spark-ignited fuels, to create the common configurable combustion platform on which the project relies.

The first phase of the project is the development of a 180-280 kW hybrid power system, to deliver a robust and trusted fuel configurable plug and play solution that produces a consistent power performance, regardless of the fuel type, ensuring long-term flexibility for the user.

In addition to Project Coeus, Perkins is also talking about its learnings on diesel electric hybrids and full electric applications. A diesel-electric hybrid demonstrator machine has been optimised to improve the efficiency without compromising on performance. In another project, Perkins has fully electrified a technology demonstrator machine with a Perkins Li-Ion battery. Both projects will be shown at bauma.

The post Perkins to help customers navigate evolving energy landscape with new solutions appeared first on International Mining.